Nessan Cleary talks to two users about their experiences with this high-volume flatbed printer.

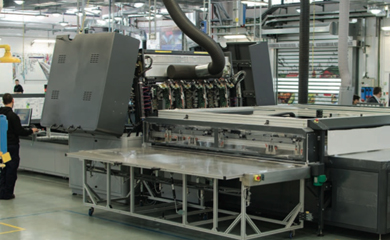

Konventional wisdom has it that screenprinting is better suited to fast throughput than inkjet but there are several digital printers that challenge that. This month we’ve been looking at one of these - HP's FB7600. Naturally print quality and the ability to handle multiple substrates are still key considerations but these printers are all about productivity, so the loading and unloading systems are just as important.

Fosco, Hayes and Hurdley, better known as Fosco’s, mainly produces point-of-sale material as well as some outdoor advertising, plus vehicle and exhibition graphics. Based in Birmingham, the company has been around since 1936 and evolved from screenprinting and sign writing through to digital printing. Today the company operates a variety of kit, including a HP Turbojet 8350 and LX850 latex printer, as well as a Vutek QS3200 and an Indigo 5500. But the bulk of the work is done on two FB7600s working flat out 24/7, one of which

David Nicholas, managing director, says that he looked at several printers but that it was by far the best machine of its type on the market. He explains: “The capability of offloading the material with the three-quarter automatic made it very attractive and the fact that it could hold down many different materials even if they weren’t laying flat, which the other machines didn’t seem able to do.”

He believes the machines are good value but admits: “We would like the ink prices to be cheaper!” He adds: “I wouldn’t say they are cheap to run but obviously we wouldn’t have bought them if they were too much.”

The operators have been trained to be able to fix most problems on site but a call to HP by 3pm will normally lead to an engineer on site with parts by 9am the next day. Nicholas adds: “You have to have a full service contract with machines like this or you are at the back of the list for an engineer and the parts go through the roof.”

Fosco’s has just become the first European company to take the orange ink option for the FB7600. Nicholas says: “When we were shown it, it was quite clearly totally different to anything we could print on the flatbeds. It’s not just the oranges, it affects reds and yellows as well so we are now hitting the correct Pantone colours for our customers.” He considers the colours to now have a beautiful vibrancy that matches the Indigo and latex printers – and that colours are consistent across a whole campaign.

However, Fosco’s has not gone for the white ink option because it’s too expensive. Nicholas says he will invest in it when the price comes down but that it’s not a viable option because of the amount of white ink that has to be put down to achieve a solid, combined with the higher price of the white ink.

However, Fosco’s has not gone for the white ink option because it’s too expensive. Nicholas says he will invest in it when the price comes down but that it’s not a viable option because of the amount of white ink that has to be put down to achieve a solid, combined with the higher price of the white ink.

Another FB7600 user is Derwent Displays, based in Denby, Derbyshire, which produces mainly POP display units, and mostly prints to corrugated boards and some plastics. Managing director Neil Haywood says that it was the ease of setting up jobs that attracted him to the machine, noting: “There’s no masking out of the bed, which the competitors said would never work, but it does.”

Derwent Displays still uses screenprinting but Haywood says that the market has changed with a lot more short-run jobs that are better suited to digital. He says that the FB7600 is very user friendly and has allowed the company to turn jobs around a lot quicker and to be more productive.

Overall Haywood is happy with the print quality and the general performance of the printer but does say: “I think the ink costs are more expensive than they make out.”

He wasn’t impressed with the white ink option, which he describes as “still a work in progress” and not something that he needs. But he goes on to say that there are a lot of extra costs with screenprinting and that overall the printer has proven cost effective.

Haywood says that HP has very good backup but he has found the service contract to be expensive. He explains that there’s a choice of service contracts, adding: “We haven’t chosen the most expensive option because that’s outrageously expensive.” Consequently some, but not all, parts are covered. But Derwent Displays did send some of its staff to HP’s training centre in Barcelona so that it can sort some problems quickly in-house.

Haywood also says that there is a software upgrade path to improve the running speed of his FB7600 but that he hasn’t taken this because he doesn't feel that its worth the additional cost. Although the printer has a weighty price tag he says it’s making money, adding: “It’s done the job that we wanted it to.&rd

Indeed, the common theme across all these users is that the MIS has led to more efficient quoting and management of jobs.

About the product

The HP Scitex FB7600 is aimed firmly at the high production end of the market and is capable of producing 500m2/hr. This translates into roughly 95 sheets per hour in production mode, though this drops to 55sph in POP mode. The maximum sheet size is 165 x 320cm and it will print to most rigid boards, including plastics, foamcore and Dibond. It can also handle flexible sheets thanks to a powerful six-zone vacuum table, but there’s no option for rolls.

It uses the Scitex-developed X2 printhead, with a fixed 42picolitre drop size, giving maximum resolution of 600dpi. The inks are HP's FB225 Scitex UV inks, with CMYK plus light cyan and light magenta, and options for white, loaded in two channels, and orange (which also comes with light black).

There’s a three-quarter automated loading option, and an optional multi-sheet loading table that allows simultaneous loading of up to four sheets. It comes with HP's SmartStream software.

Alternatives

INCA DIGITAL

Perhaps the most obvious alternative is the Onset series, developed by Inca Digital and distributed by Fujifilm. There are several different Onset models, including the S40i. This produces prints up to 3.14 x 1.6m and takes substrates up to 50mm thick. It uses Fujifilm Dimatix printheads and resolution varies from 600 to 1000dpi, with a maximum throughput of 560m2/hr. This translates into 35 to 112 full beds per hour. It uses Fujifilm UV curable inks, with a six-colour inkset. It also comes with a three-quarter loading system.

DURST

This company has a number of high productivity flatbeds including the Rho 1030, which can print up to 1000m2/hr. It has a maximum printing width of 2.5m and resolution of 600dpi. The base model is CMYK, with options for light cyan and light magenta, or orange with green or violet.

EFI

The new HS100 was first shown at Fespa 2014. This is a hybrid system, equally able to handle boards and roll-fed materials. It’s 3.2m wide machine with a maximum throughput of 100 boards per hour, though this drops to 60 boards per hour in its POP mode of 600dpi. It can take up to eight colours, including white and has the ability to vary the print finish from matte to gloss. Naturally, it comes with EFI’s own Fiery XF Rip.

AGFA

Agfa sells the Jeti range including the Titan X. It takes boards up to 3 x 2m and rolls up to 3.2m wide. It can produce up to 266m2/hr. The printheads used are Ricoh Gen4, which have 600dpi native resolution but being greyscale heads can produce up to 1200dpi apparent resolution. It uses Agfa’s own UV inks with a six-colour inkset, but there’s also a white ink option.

{jathumbnail off}