Nessan Cleary looks at just what sort of print quality you can expect from this entry-level latex printer.

The HP Latex 260 is an entry-level latex printer that offers an alternative to solvent printers, particularly for more office-alternative to solvent printers, particularly for more office- based type users. It's based on the same chassis as HP’s T7100 CAD and Z6200 graphics printers, albeit with additional heaters to cure the latex inks.

The Latex 260 is a roll-fed machine that takes media up to 155cm wide, which is about the maximum width that a single operator could cope with. One really nice feature is that everything, including media loading, can be done from the front of the machine so that the printer can be pushed up against the wall out of the way, giving it a very small footprint (the actual machine dimensions are 2465 x 690 x 1370mm).

The machine can automatically update its own software from HP's network. Operators can check the status of the machine via the Internet and can run any necessary maintenance remotely. Otherwise, all the machine functions can be run from the front panel, a small LCD screen on the right hand side of the printer. Thus the panel tells the operator how much ink is loaded into each cartridge and advises when the heads need changing. The front panel also provides step- by-step instructions for common maintenance tasks.

Tom Skinner, machine sales specialist at dealer PSW, says that very little maintenance is needed, with no daily startup checks. It can be left unused for weeks at a time without worrying about ink drying out in the nozzles.

There's a choice of Rips from Caldera, Wasatch and Onyx, though Skinner uses the Onyx “because manufacturers tend to make profiles for Onyx quite quickly.” There are several variations of Onyx but for the test the recently developed Onyx Thrive was used; this has been built on the Adobe PDF print engine.

Thrive will support up to six printers and you can process up to four jobs at a time. It also includes an accounting element that shows the costings for each job.

Inks and media loading

The inks are HP’s own water-based latex inks. As with all the HP latex printers, the Latex 260 uses CMYK plus light cyan and light magenta. The cartridges hold 775ml of ink, which costs around £95 (prices seem to vary between £90 and £105 so it’s worth shopping around). Where a cartridge is running low it’s possible to take it out and put it to one side for later use, without worrying about the ink drying out. The cartridge will depressurise but Skinner says it can be put aside for up to three months. It’s a handy tip if you want to load a full cartridge to leave the printer running overnight but don’t want to waste a nearly empty one.

There's a maintenance cartridge, held in a panel underneath the LCD that can be used to flush fluid through the heads for maintenance tasks, without wasting ink on mundane tasks like cleaning nozzles. This costs around £50.

The printheads are HP thermal heads with a fixed 12 picolitre drop size. Each head has two colours and there are six heads arranged in two rows so that the colours are interlaced. Each head has more nozzles than are actively used, and the machine checks for blocked nozzles and maps to other nozzles when they become blocked. But as with all printers there’s no rule as to how many blocked nozzles it takes to fail the head because it depends on the disposition of the blocked nozzles. So instead the recommendation is to change the heads after one litre of ink, but you can ignore this and run the risk of the heads failing in the middle of a print run. Careful maintenance, mainly wiping the nozzles periodically, means the heads can keep going until there really are too many nozzles blocked and then it fails. The heads cost around £60-70 and are easily changed.

The Latex 260 can handle media up to 40kg. It’s fairly straightforward to load. There's a built in bench so that operators just have to lift the roll onto the bench and feed thereel through it. Folding the bench up then drops the reel into place. All the loading and tension bars are supplied with the printer with no further options. The printer also supports double-sided printing. Skinner says that it’s accurate up to 5mm for front and back registration.

Costs

The HP Latex 260 costs £9,999, which includes a set of inks and some media samples. In addition there’s a further £450 for installation, plus the cost of a Rip - an Onyx Rip is around £1,800 - £2,200 depending on the version. HP may evaluate the pricing depending on the take up of this discounted price but as a rough indicator the cost was previously £14,500 including the installation and an Onyx Rip. There are no optional extras so you get everything in one package for one price.

On Test

We ran the test at PSW, a family run graphics bureau that also sells the Latex 260 for Art Systems. It was established 36 years ago by Matthew Skinner, who now runs it with his sons Phil and Tom. The machine sales side is run by Tom Skinner, who used to sell Macs which has left him with a good customer base amongst design studios.

We ran the test at PSW, a family run graphics bureau that also sells the Latex 260 for Art Systems. It was established 36 years ago by Matthew Skinner, who now runs it with his sons Phil and Tom. The machine sales side is run by Tom Skinner, who used to sell Macs which has left him with a good customer base amongst design studios.

We normally print our test files to paper, in this case Art System's own Xativa-branded satin poster paper 200gsm. Art Systems supplied a profile with the paper but it took a while to get this to work and eventually Skinner had to edit the profile to reduce the curing temperature.

HP claims a maximum speed of up to 22.8m2/hr in its four-pass mode. However, a couple of users spoken to on the day of the test said that they would regard 12-pass as a production mode for day-to-day work in order to ensure a good enough quality, which has a speed of 7.6m2/hr, though for some jobs you could get away with the 8-pass mode, at 10.6m2/hr.

The printer takes a certain amount of time to adjust the curing temperature. However, if you were printing multiple copies of a job then the machine should be able to print continuously with no need to wait for the temperature adjustment. But otherwise you can expect to wait four to five minutes for the temperature to settle.

The printer takes a certain amount of time to adjust the curing temperature. However, if you were printing multiple copies of a job then the machine should be able to print continuously with no need to wait for the temperature adjustment. But otherwise you can expect to wait four to five minutes for the temperature to settle.

We used two A0-sized test charts, with one having a number of solid Pantones, plus some pictures, and the other having an IT8 chart, a large Reflex Blue gradient and a number of photographs. Both of these have similar print times, with the first, using the 12-pass mode, taking 11.12 minutes, including 2mins 40secs to Rip the file and send it to the printer. The 16-pass mode was slightly slower, taking 13.09 minutes. Ink usage was similar for both - 15.602ml for 12 pass and 15.967ml of ink for 16 pass - which Onyx calculates as costing £2.54.

There’s very little difference in terms of print quality between the 12-pass and 16-pass modes. The colours are rich and vibrant, with a glossy feel that seems to leap off the paper, though there is a slight magenta cast, which is mainly noticeable in the monochrome image. There is a very faint hint of banding in some of the large Pantone swatches, but it’s only detectable when viewed from within a few inches and then only if you’re looking for it.

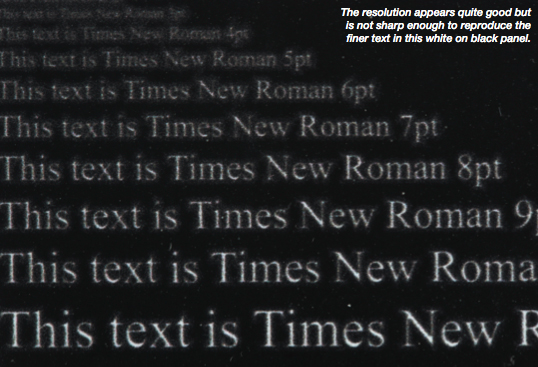

The prints appear sharp with text just about legible at 4pt, and quite readable at 5pt. However, the white on black text did not come out so well, with a distinct lack of whiteness - the text is more of a dark grey and not really legible below 7pt.

Conclusion

HP has been meticulous in ensuring that the Latex 260 is easy to use. It's relatively inexpensive, both to buy and to run, and yet capable of fulfilling many applications from posters to banners and flags. The print quality is excellent, but it's essential to queue jobs up to keep the machine running at temperature in order to get real productivity out of it.

{jathumbnail off}