Longier has produced a flatbed printer at a reasonable price but does it have the print quality to compete in the UK market? Nessan Cleary puts tries it out.

Whether deserved or not, Chinese inkjet printers have generally had a poor reputation here in the West for quality and reliability. But Paul Serellis of Eazy Print, whom we met for last month's Hands On, was so enthusiastic over his Longier flatbed that we were intrigued enough to have a proper look ourselves.

Longier is based in Changzhou City, near Shanghai. The company was set up in 2011 by Dan Wu, an industry veteran who had previously developed the TS series of printers at Teckwin and overseen production of Apple devices at Foxcon. Longier launched its first flatbed in 2012 and now also produces ceramic and textile printers.

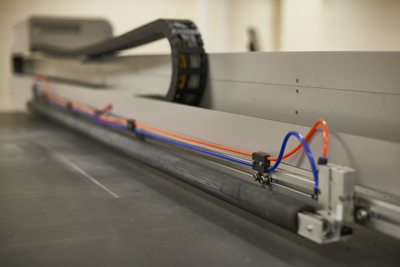

But for this test we’ve looked at one of the wide-format flatbeds, the Hunter FR3750. This is an LED UV printer capable of producing up to 70m2/hr. It takes boards up to 55mm thick with a maximum printable area of 2500 x 1450 mm. It comes with a built-in roll-to-roll system – you can order it without the roll-feeder but you can’t retrofit it as it’s an integral part of the machine. The roll holder is on an arm that comes out when you unlatch it so that even a heavy roll is easy to load. There’s even an option for taking larger 2 x 3m boards that involves putting a belt on the roll-to-roll holder so that it acts as a conveyor feeding the boards across the bed. Tables can be added either side to take the boards.

The UK distributor is Hallmark Equipment Service, which is run by Gary Hall, and mainly handles service and support for wide-format printers. Hall cut his teeth with a service agreement for the DuPont Cromaprint machines, many of which are still running in the UK thanks to his careful servicing. Over the years he suggested numerous small improvements to these printers as well as changing the ink supply from Dupont to Nazdar and adding a PhotoPrint Rip from SAi.

He's taken more or less the same approach with the Longier machines, which are now running the latest generation Nazdar 710 LED ink. The inks themselves come in one-litre bottles and sit in the cabinet on the left so that it’s easy to change them.

An engineer by training, Hall has taken quite a hands-on approach to these printers, offering suggestions to Longier and making a few modifications himself, such as adding a roll bar behind the gantry to improve the image quality on roll-to-roll prints. He says that one of the things that attracted him to the Longier brand was the company’s willingness to take on new ideas and improvements.

The company is continually tweaking the printers to improve them. So, for example, the machine we tested now comes with water cooling for the LEDs rather than the original air cooling. Further improvements include filling the beam with high-density foam to make it quieter. The head carriage is driven by a belt and its movement reverberates through the beam producing a distinct but low-level noise though the foam should stop this.

The standard machine comes with a single row of up to eight printheads and can be configured with two sets of CMYK, or with CMYK plus light cyan, light magenta and white, or with spot colours. There are two channels set aside for white ink, which is recirculated right through the system all the time that the machine is on at the mains to prevent the ink clogging in the heads. There are 16 channels in total so that a second row of heads could be fitted to double the speed.

It uses Konica Minolta KM1024 printheads with a fixed 14pl drop size. Hall adds: “We use the MH variants which have got heaters in the heads rather than heating the platen as this gives you better adjustment for ink placement.”

It’s possible to use 42pl drop sizes for the white inks or to fit a variant with variable droplet sizes with a 6pl minimum. HES will add more heads and change heads over but the six picolitre heads have to be specified from the start because they have different electronics.

There are crash sensors either side of the carriage assembly though there don't appear to be guards on the heads. There’s a motor to adjust the head height but you need to know how thick the material is as you have to tell it how high above the material you want the heads to be. Hall says there are plans to add a sensor to set head height: “We are looking at a laser system in the future that should be retrofittable.”

The maintenance station is on the right hand side and is easily accessed. Hall says that the maintenance is fairly simple and that when the machine is switched on in the morning a small amount of ink needs to be primed through the nozzles and then wiped off.

Although HES is the distributor, the actual sales in the UK are handled through QPS. The Hunter FR3750 costs £87,000 with a single row of heads and the roll-to-roll option. There's an upgrade option of adding a second row of heads and the machine can be ordered as such. However, Hall says that it’s cheaper to buy the heads locally and that he'll fit heads that customers source themselves. The KM1024 heads should come in at around £2,000 each including the board and ribbon cables.

The inks cost £90 for a 1 litre bottle for all colours including white and this also includes telephone and remote support.

The price includes a one-year warranty for parts and labour and six months for the heads for electronic failure but not for damage. Hall will also service the printer every six months.

After the first year there is a service contract, which works out at around £350 per month. But Hall says that people can take out asset insurance, which is much cheaper when the machine is new and which covers the heads for damage.

The price also includes a Photprint Rip (Cloud edition) from SAI, which appears to be the same as FlexiSign. Hall has preset it with four modes: Poster at four passes and 360 x 1080dpi; Production with six passes, also 360 x 1080dpi; Quality with eight passes at 720 x 720dpi; and High Quality with 12 passes at 720 x 1080dpi.

On test

We tested the FR3750 at the HES facility in Cambridgeshire. Our standard test involves printing two A0-sized test charts – one with mostly solid Pantones and one with mostly photographs. We print both of these twice, using the printer’s Quality mode to gauge the sort of image quality the printer is capable of, and Production mode to get an idea of the productivity you can expect.

All images were printed in bi-directional mode with feathering turned on. Hall explains: “We can put the ink down with or without feathering which is adjustable so you can interpolate the front edge to eliminate the cure banding.”

The Quality mode used eight passes with 720 x 720dpi resolution. This took 7.30 minutes for the photograph chart and 7.27 minutes for the Pantone chart, using 11.11ml and 12.78ml of ink respectively. The Production mode used six passes with 360 x 1080dpi resolution. This took 5.39 minutes for the photographs chart and 5.43 for the Pantone chart, and used 9.05ml and 10.24ml of ink respectively.

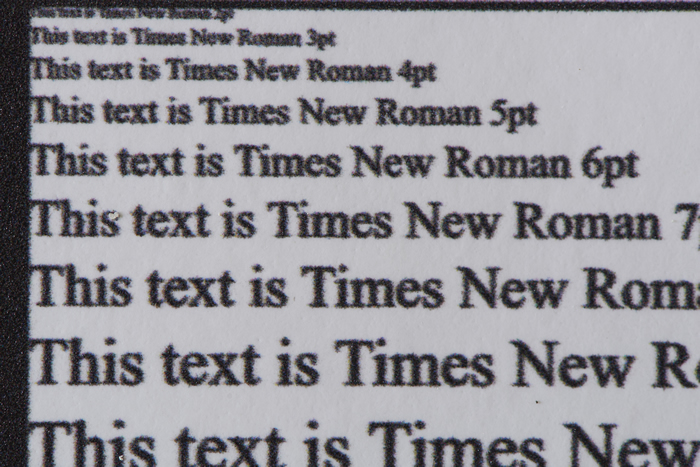

The image quality is superb in the eight-pass mode with no obvious problems anywhere. The images were reasonably crisp, the solids were smooth and the text was legible down to 3pt, though it’s not the sharpest that we’ve seen. There is a further High Quality mode with 12 passes, but Hall says that this will be slower and won’t make much difference to the quality and there certainly isn’t any problems with the images as they are.

There's not much difference in the six-pass mode. The colours are slightly anaemic so that some of the solids are a little weaker than they should be and some of the photographs lack bite, which in both cases is most noticeable in the reds. The text is not quite so sharp but still just about legible at 4pt. The reflex blue gradient is not quite as smooth as it could be, with a very slight step, only noticeable from very close up, and wouldn’t be a problem for any commercial work.

Conclusion

We were impressed with the results from our test, with the Production mode being good enough for most applications and the Quality prints being suitable for close-up viewing. The machine is fairly basic but it was reasonably quick and seems quite easy to use. Hall is committed to getting the best out of it and has a proven track record in servicing. He certainly seems to be onto something, with one machine already installed and running in the UK and a further five ordered since the recent Sign and Digital UK 2015 show.

{jathumbnail off}