Want to be able to transform customers’ 2D images into photorealistic 3D display products? Then maybe you should talk to StackaWraps

Two years ago Image Reports carried a feature on StackaWraps and its novel 3D printed product offering. Now it hopes to extend its patent pending PanaWrapping services via relationship building with large-format PSPs. Worth considering?

Well, the company has been continuously developing its PanaWrapping technology and has rolled out a number of 3D printed products that it believes can “reinvigorate display branding internationally,” pointing out that there’s been interest from FMCG CPG brands such as Coca Cola, Kellog’s and Carlsberg, and that “the latest discussions are of course under wraps but 2019 is quickly proving to be a massive year”. Momentum is building with its latest offering - PanaWraps - which fills a gap in the market for greener 3D branding products and which it believes could provide new opportunity for partnering PSPs.

StackaWraps Digital Studios CEO, Richard Peter, says demand is such that the only way to get PanaWrapping to clients quickly enough to meet the demand is to join forces with the leading experts in large-format print. “I’m renowned for my high energy levels but even I can’t keep up with the speed we’re having to scale-up to as orders go exponential, from a couple of hundred in the first three months to orders in their thousands these last few weeks. If large-format printers want to get in on the PanaWrapping action now is the perfect time.”

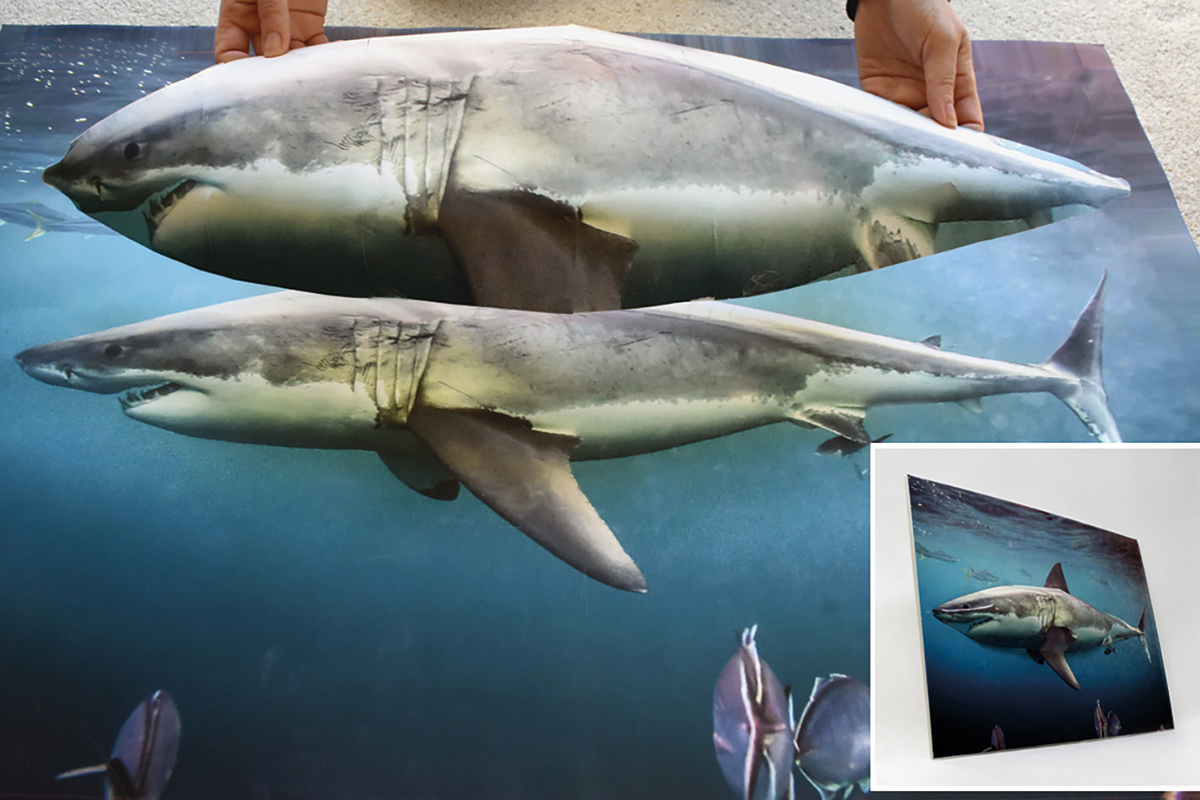

So what’s it all about? Basically, PanaWrapping is a technique developed over the course of the last two years by StackaWraps Digital Studios (SDS) to convert 2D images into 3D graphic products. It takes a 2D image file, keeps the full photorealism of the original image, enhances sensory realism without distortion and generates technical print-and-cut files for output to be made into 3D products.

Last summer Stackawraps introduced Shelfies for POS and Panoramic Posers and Popheads using the technology - now it has brought PanaWraps to market.

Made from as little as two pieces of recycled (and recyclable) material, PanaWraps are flat-packed for low-carbon logistics, and offer a plastic-free alternative to other 3D visual branding products, important in today’s landscape where, as Peter points out: “Non-sustainable materials like fibre glass or vac form are considered a less green friendly approach to displays than recyclables and power-hungry sources such as inflatables are becoming a no-no for many consciences brands and retailers. Large companies such as P&G are utilising displays with high green credentials and retailers such as TK Maxx are phasing out the use of all non-environmentally friendly display accessories such balloons.”

Print partnerships between StackaWraps and PSPs have increased fivefold over 2018-19 from the original hand-tailored 3D StackaWraps for product replica FSDUs and POS, to PopHeads 3D posters for the consumer marketplace via Amazon in conjunction with NEC Grafix.

The new PanaWraps product has been perfected for any size, any application, 3D displays. Peter explains: “Printers simply provide the 2D images from their clients to the Stackawraps studios and we work our magic to generate files for print-and-cut 3D elements bespoke to their needs. The initial set-up and tooling is charged at a one-off per image fee subject to detailing - we send them the files and support them through prototyping and first runs with a royalty percentage from the sale paid to StackaWraps on a project by project basis, dependant on order quantities.”

Boston, US-based Abbot Action has already been signed up as a partner - chosen due to its fully solar panelled plant. The digital PSP is expected to select a number of other US based manufactures to take the product out into the marketplace. Here in the UK, it is hoped PSPs will see the benefit of taking it out into the market too.

Stackawraps’ co-founder Natasha Leigh says the company’s innovations are in response to a need for print to survive in an increasingly green-conscious trade that’s fast shifting from traditional methods to a more eco-mindful industry. “With interest from global brands overtaking manufacturing capacity, it’s time to expand the PanaWrapping 3D print product possibilities via more PSP partnerships. For the lowest carbon footprint possible, we need multiple locations to meet the surging demand for PanaWrapping. We’re looking for at least a half a dozen across the UK and another 12 across the USA.”

The company points out that the UK’s 2050 zero carbon pledge has upped the ante for greener thinking, and that G7 countries are progressively seeking to phase out non-environmentally friendly industry practices, meaning that suppliers of retail and exhibition displays are having to think way outside traditional methods to compete when it comes to eye-catching solutions. “There is little place left for inflatable, solid builds (vac form and injection moulding) and for costly haulage items that don’t tick the green boxes of large international clients. The R&D team at StackaWraps spent the last four years rethinking and reinventing ways to breathe fresh life into printing and are confident that PanaWraps is the start of a new 3D journey for global print partnerships,” says Peter.

He adds that the time and money invested developing the team, the technology and the applications has been extensive and that the commitment of staff has been inspirational. “Sharing this innovation with the rest of the industry has been a great leap of faith and we’ve been rewarded with loyalty and enthusiasm. Those working with us have challenged our capabilities and forced us to evolve to perfect the process. We are confident this is the way forward and welcome interest from forward thinking minds across the international print industry who are looking to form mutually beneficial long-term commitment to print development.”