Are we about to see a commercial inkjet head repair facility service operating in the UK? Well, work is underway…

Industrial inkjet printhead failures due to missing/deflected nozzles are a major source of financial loss to PSPs and result in tens of millions of pounds worth of high value electronics being scrapped. But that may be about to change thanks to work being undertaken by Philip Keenan at Camscience, supported by Cestrian Imaging and Nazdar.

At the end of this month (May 2016), a feasibility study from a research project - started last December - will conclude with a proposal for launching a commercial printing technology repair facility. The intention is for a service that will be extended to printhead personality boards, PCBs, and eventually entire printing systems refurbishment for an open-access digital innovation centre.

According to Keenan, the project should be of interest to large-format digital printers, printer service and printer warranty providers, and OEM printer and printhead manufacturers who wish to reduce their warranty losses, reduce the impact of printhead and printer obsolescence to the printing industry economy, extend the life of their printer consumables, and contribute in a big way to reducing the UK’s printing industry’s impact to the environment.

“Despite printheads having a design-life of five years or more, printers have a limited set of options available to them to recover a printhead that malfunctions. In many cases, actions such as purging the printhead with ink, wiping the printhead nozzle plate, performing a nozzle-priming action etc., are unable to recover the printhead and the printer has no alternative other than to swap the underperforming printhead with a replacement and consign the rejected printhead to landfill,” says Keenan, who goes on to explain the origin of his project.

“Camscience Limited partnered with ink manufacturer Nazdar and large-format PSP Cestrian Imaging to enter, and win, an Innovate UK Feasibility Studies competition for ‘Circular Economy Business Models’. The intention was to demonstrate the feasibility of remanufacturing industrial printheads and to keep them in production longer, minimising wastage of high value printer parts. The upshot was a pilot project that tests this concept.

“Camscience, the lead partner developing the printhead recovery technology, chose to work with Cestrian Imaging because of the company’s environmental awareness and performance - displayed prominently on Cestrian’s website is its metrics for recycling and materials recovery, along with elimination of hazardous waste and landfill. Likewise, ink manufacturer Nazdar was asked to be a partner as it could show environmentally conscious credentials. Both partners will support the testing and evaluation of printheads recovered after processing.”

Keenan himself has been part of the inkjet printing industry for 20 years, starting his career with Hewlett Packard USA as a printhead developer and manufacturing engineer, later becoming an integrator of industrial printheads in industrial presses. He designed the colour ink and printing systems for eco-friendly 3D colour printer manufacturer Mcor Technologies.

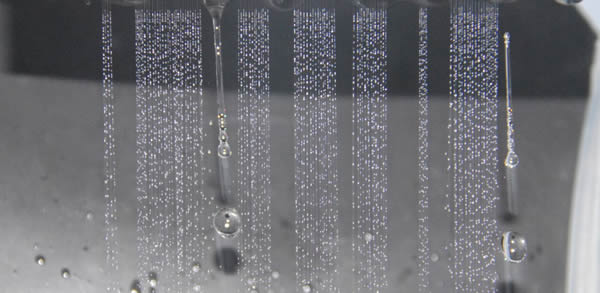

He adds: “The processes whereby inkjet printhead nozzles develop misdirected jetting behaviour and subsequently blocked nozzles, are complex. However, for UV inks, it is possible that local cross-linking of ink occurs in proximity or inside the nozzle itself due to a combination of thermally accelerated processes and stray UV lamp energy reflection back to the printhead surface over time.

“Other causes may include inkflow dead-zones in the printhead, or other regions where there may be static flow pockets where ink debris may collect and be deposited. End nozzles in some printhead design may be prone to this phenomenon. Combinations of these events lead to localised reductions in inkflow, causing weak and deflected nozzles and the reduced flow-volume of ink and flow-obstructions in the printhead cause further formation and growth of ink deposits until multiple nozzles fail.

“Camscience is using experience gained in the semiconductor and printhead manufacturing industries to deconstruct the cured UV ink residues present in printhead nozzles and channels in a safe and controlled manner so as to restore these printheads to an as-manufactured condition and allow their return to printing service.”

So will we see a commercial inkjet head repair facility service operating in the UK? Watch this space.