…is that its lifecycle isn’t as green as it could be. But are things changing? Netherlands-based ColGraphix, a global distributor of products for the digital dye-sublimation sector, believes it could be. Here’s how.

OK, so sublimation printing on textiles is the most sustainable among all textile printing processes. Much has been written on the basic environmental advantages of this process, but to recap - sublimation printing creates zero waste water, uses harmless water-based inks and paper that can then be easily recycled. All good - but could the environmental aspects your sublimation operations be still further improved?

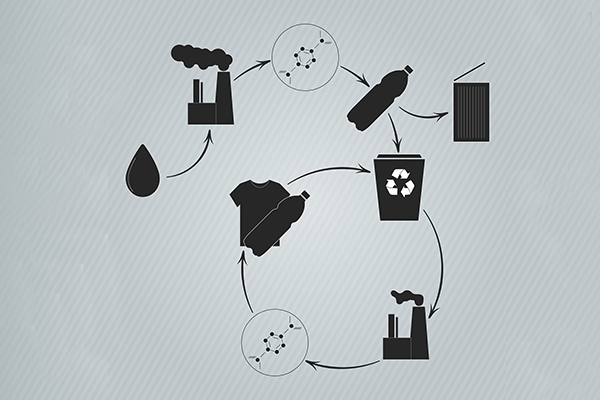

The polyester textiles uses for sublimation printing are man-made fibre created from petroleum products through a process called polymerisation. Not only does this process consume fossil fuels, it results in by-products that are toxic, pollute the water and air, and can cause several health issues. ColGraphix does not claim that man-made fibres are a bad thing for the world in general - at a global level, man-made fibres consume only about 0.8% of the total crude oil production, while using far less land and water than natural fibres. Today he finger is in pointed in particular at the polyester life cycle.

The main wastage of the digital dye-sublimation process is used transfer paper and polyester fabric off cuts. Both of these by-products are recyclable, yet in the experience of ColGraphix not many sublimation printers make the conscious choice to do that.

“There is no fitting infrastructure”, “I do not have the time to make this work” and “I am too small to make a difference” are the typical responses as to why sublimation PSPs do not recycle. They have a point - how can a small player make a difference on their own when the infrastructure is not in place?

At the upper end of the supply chain manufacturers are falling behind with their efforts to recycle polyesters. Approximately 37m tons of polyester are produced and consumed around the world annually. Each year, more and more virgin polyester is created instead of existing materials being reused. Why? - because it’s cheaper for manufacturers to use virgin polyester than invest in the recycling process and, unfortunately, not many manufacturers are willing to pay the price of creating a more sustainable product. There are, however, a notable handful of manufacturers that are taking a more responsible line and placing sustainability at the core of their operations.

During ColGraphix’s research within Europe, the German textiles manufacturer Verseidag stood out as a notable example of such company. Beyond complying with European and German standards this company has adopted voluntary measures to benefit customers and the environment.

Verseidag uses state of the art technologies to ensure zero harmful emissions and resource-efficient processes. Furthermore, through its scrap materials take-back programme, Verseidag provides the infrastructure for clients to easily have their scrap polyesters recycled. Lastly, the sustainability aware customer can purchase recycled polyester textiles without having to pay a higher price than a virgin polyester alternative of the same textile - it is the manufacturer that makes sure it handles any price difference in the raw polyester materials.

This is only one example, but it provides hope that there are responsible manufacturers in Europe, and that an appropriate infrastructure does actually exist for those who wish to make their sublimation printing process even more environmentally friendly. Ask for media that fulfil greener criteria - switches will barely cost you anything, yet will give you the pride and satisfaction that your business is doing its share in protecting our planet.