Be clever and think smart. Software developments and integrations mean large-format PSPs have more opportunity than ever to gather and analyse data from across the whole of their operations, and to use that intelligence to make them more efficient and profitable.

You know it - the better you gather, analyse and apply your business data intelligence, the better off you’ll be. And the good news is that the wide-format sector is now getting a proper share of the software attention that has for so long been focussed on more mainstream - and less problematic - areas of print.

As Nick Benkovich, VP portfolio product management, eProductivity Software, points out: “Now more than ever, with rising materials and labour costs, labour shortages, the continued decrease in run length at the same time as increase in product complexity, it is critical that a business understand and analyse their operation from order acquisition to shipping.

“The challenge for many PSP’s is their deep knowledge and legacy years of experience in a largely stable market that allowed them to often make gut or instinctive decisions. Today with the changing landscape we are seeing more and more businesses with the need to analyse everything.

“Often PSP’s can instinctively tell you who the largest revenue customers are or what is the greatest volume by product types produced. This is just the start. What a business needs to understand through collection and analysis of data is what are the most profitable product and customers. This needs to include everything - from order acquisition costs (online, email, portal, salesperson), to job management costs (estimating, planning, customer service, scheduling) as well as true, not estimated manufacturing costs.

“This is where a solid BI [business intelligence] tool comes to the front. Slicing and dicing the data to see what the most profitable product lines and customers are, and how that has changed over the past months, quarters and years. So where do you start? A fully integrated end-to-end system with centralised source of truth data for every touch, step and operation of a customer interaction or job allows a deeper, truer picture of where the real profits are and where adjustments need to be made. ePS provides a fully integrated suite of solutions from order acquisition to shipping, capturing time, materials and subsequently costs to really understand where you as a business need to focus your time and energy to maximise profits and grow.”

Tharstern’s chief business development officer Lee Ward points out that actually, many a MIS system holds an incredible amount of useful data, but that the majority of users are not making the most of it. “It’s often assumed that an MIS only holds data from estimating and sales, but as technology has advanced, the systems now hold data from every area from the initial marketing all the way through to delivery, but it’s often not used correctly.

“Our customers are encouraged to use a business intelligence platform, whether that’s provided by us, or through a third-party AI tool such as Power BI or Qlik. These sorts of tools pull in data from multiple software applications and give a full view of how your business is performing. A lot of PSPs collect data, but they have no idea what the numbers are showing or what they can do with it. With software like Power BI you can really drill down into numbers.”

Ward adds: “The one piece of analysis we’ve really tried to push our customers to carry out this past couple of years, is to create a BCG matrix using the historical order data from their MIS, so they can see which of their products and target sectors are making them the most profit. Often the results of this analysis will have changed because of the pandemic, so it’s more important than ever to carry this out and reassess sales and business strategies based on the results.

“When we speak to new contacts, becoming more profitable and efficient are two of the top things they want to achieve with an MIS. We’ve developed some specific features that will really benefit the large-format market.

“Our Sheet Optimisation tool with Insoft IMP was developed a few years ago, but the ability to create complex, production-ready layouts for variable-sized rectangular shapes and non-rectangular shapes from within the estimating area of your MIS has proved very popular. The interaction with IMP means efficient layouts can be created, even for the most complex shapes.”

The company has also developed a few new features more recently: Distribution Uploader allows users to manage the distribution of complex multi-location print campaigns by importing customer-provided CSV files into the MIS; Smart Shipping automatically calculates the transit time for each location and identify the required ‘ship by’ date in order to meet the customer’s due date; Auto-packing creates packing groups per location and works out how many of each product are needed in each group.

At printIQ UK marketing manager David McGuiness says the company is constantly working to meet changing user demand, and releases about 15 new features to its cloud-based system per quarter.

“Our development team is part of what you buy into given that software moves at such a pace’ he stresses, and points out: “Our R&D is focused on OEM integration to expand system capability. For example, Zaikio is currently being developed as a connection.”

Some of the most important features introduced in recent months include: Live Pricing, which links to major Web-to-print systems like Infigo and feeds pricing to its interface in real time; Shipping integration, which provides automatic updates on when and where the product is; Linear usage in m2 that provides accurate calculations of material used; Carbon Quota, which allows estimations on the best way to produce a job; and Link, which integrates Print IQ to numerous websites - allowing print management sites to place orders, and also allowing two print companies to work together if they have different needs or equipment.

“Many of these features are part of our V44 update and because we almost develop in real time there are many other enhancements coming, usually small features that improve our connectivity or user experience,” says McGuiness.

He acknowledges that a reduction in staff levels through the Covid-19 pandemic has created a need for systems that allow staff to interact efficiently and cover more roles within a business. “In short companies need to do more with less people. Print IQ lends itself to this requirement with some of the best GUI’s in the industry which are intuitive and simple to understand.”

McGuiness continues: “Accurate reporting about the business costs and what is happening within that chain of events must be easily accessible. Annuities management also become crucial to incorporate, as has the increasing cost of consumables, utilities, fuel for vehicles and labour costs given the rises we are seeing. Print IQ allows a business to update these costs by adjusting the square footage cost, hourly labour rates and even factory costs.”

“Even before the pandemic, printing business owners were facing multiple difficulties: how to increase the efficiency of their operations by doing more, faster and at lower cost; how to keep key customers up to date on the status of their jobs in real time; how to ensure that jobs are delivered as promised. Then Covid piled on the pressure even more, making remote tracking of job and equipment status even more valuable, and making labour availability much more variable and unpredictable, says Martin Bailey, distinguished technologist at Global Graphics Software, part of the Hybrid Software Group, which developed the SmartDFE which adds print to the fully automated Smart Factory.

“A complete solution to all of these problems obviously requires investment in a wide variety of software and equipment, and restructuring workflows to increase automation with a careful balance of minimising touch points, while retaining enough to ensure good process control,” Bailey continues. “And a key part of any automation, or at least automation that works, is to ensure that there is good feedback from every step of every process. You can’t react to something that you don’t know about.

“From the point of view of the DFE on a printing device, that feedback can include a huge range of information, such as: a prediction of how long a job will take, both in preparation (Ripping, colour management, halftone screening) and how long the press will need to run for. It can also be used to educate customers who repeatedly send inefficiently constructed PDF files; reports from preflighting in support of failing early, with minimal wastage in terms of time and materials, if the job is going to fail at all (eg. because a font is not available); a report of the amount of ink and media that will be used to print each job, in support of more accurate pricing and invoicing; feedback from inline and nearline inspection systems, in support of identifying print issues as early as possible and of reporting to buyers around colour reproduction tolerances etc.; reporting on issues that stop production on a press, such as maintenance, substrate breakage, insufficient ink etc. All of these can feed into a system that will alert production management if current plans need to change and provide account managers with the information they need to ensure that customers are happy.”

At Fespa Global 2022 Dataline Solutions was showcsing the latest in its MultiPress offering, having said that generic project management software, accounting packages or other ‘island’ solutions do not meet the specific requirements of the large-format print sector. Dataline has around 80 certified links with partners and is constantly adding to that number. At Fespa it was highlighting a number of interfaces for this market, including a new link with Caldera PrimeCenter.

In May Enfocus released an ‘Invest small, print big’ Switch-based workflow automation package that integrates with existing workflows in the wide-format sector. The adapted Switch solution connects MIS, proofing, Web-to-print, PDF preflighting, customer approval and production preparation processes.

Switch product manager Davy Verstaen said of the development: “Removing repetitive and manual tasks and visualising workload comes from a data-driven workflow. Having the ability to build a solution that connects everything and remains scalable is exactly what Enfocus Switch is designed to do. Our Switch-based solution enables printers to make people, processes and equipment more efficient and effective.”

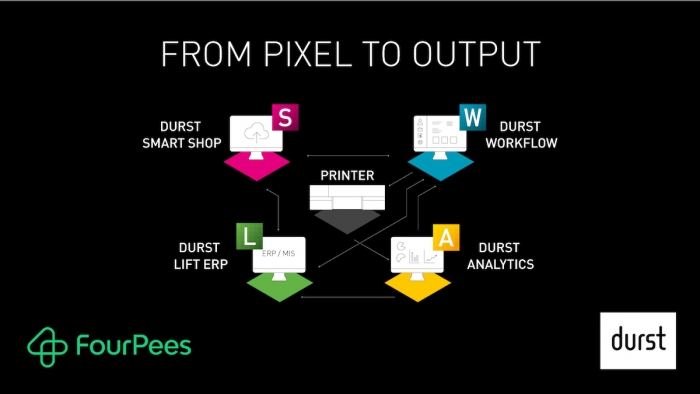

The move to smarter working is, increasingly, prompting printer manufacturers to partner software specialists if not build their own internal teams. Just a couple of months back Four Pees became an integration partner for the Durst software and solutions division. It means Four Pees will help Durst implement its ‘pixel to output’ strategy and integrate its software solutions such as Durst Workflow or Durst Smart Shop at its clients.

Four Pees will help Durst implement its ‘pixel to output’ strategy and integrate its software solutions

Durst Group founded its software and solutions division in 2019 with a team of over 60 people to provide intelligent and straightforward software solutions to streamline the complete print process. The range comprises: Durst Lift ERP, a cloud-based ERP/MIS system; Durst Smart Shop, an e-commerce solution for customisable print products; and Durst Workflow, a solution for fully automated management of prepress and production tasks. The solutions are tailored for digital printing and are optimised for a mixed-vendor production environment.

Michael Deflorian, business unit manager, Durst software and solutions, says: “Durst is known for quality, both in hardware and in the area of print automation software. We wanted to serve our customers even better in consultancy and integration and make our product portfolio easily accessible. We started looking for an experienced integration partner in Europe, and Four Pees quickly appeared on our radar. They have a proven track record in delivering complex automation projects. When we started talking to each other, we found that we were very complementary to each other in the way we work.”

At Fujifilm Europe, workflow product manager John Davies, points out its partnership with Tilia Labs. “The new Acuity range of wide-format presses, announced in 2021 as a ‘new blueprint’ for wide-format, is built to offer exceptional ROI, and being able to offer the right workflow tools to maximise its potential, is vital. tilia Griffin, developed by Tilia Labs, helps wide-format print businesses to improve their workflow efficiency by enabling jobs to be planned or scheduled, based on the user’s requirements, prioritising speed, cost or media utilisation depending on the individual job requirements. Ultimately, it can help print service providers to keep their productivity up, and labour costs and waste down.”

As a commitment to driving software innovation, HP recently announced the opening of a new Centre of Excellence in Valencia, focused on software development. Oscar Vidal, global director, large-format, HP says: “While our hardware will continue to play an essential role, we are continuing to invest in software-led digital services to help PSPs gain greater visibility and control over their operations.

“Solutions such as HP PrintOS have proved indispensable by helping customers stay on top of production wherever they are, while also enabling them to make better, data-driven decisions. But remote access software is not enough as a standalone tool - intelligent automation is also key. In this regard, the HP Applications Centre is helping customers to easily integrate a suite of design apps into their own websites, enabling automated production and order management. Elsewhere, the HP Configuration Centre allows for customised substrate settings, such as colour configurations, across an entire fleet.”