The digitally printed textiles market is growing, but is if for you? Nessan Cleary reports on the latest technological developments for textile print.

The basic concept of using dye-sublimation to transfer digital inkjet prints to textiles has been around for ages, but we’ve seen considerable growth in this area in the last couple of years, as evidenced by the growing number of dye-sub printers and emergence of several niche trade shows.

But this growth is almost entirely down to the fashion industry having adopted digital technology to print garments, plus a burgeoning home furnishings market. Most inkjet printer vendors agree that there's little crossover between these markets and the graphics market, but believe that this is because few wide-format PSPs have worked out how to sell into the garments and furnishings market.

Phil McMullin, sales manager for professional graphics for Epson UK, firmly believes that there's a business opportunity from cross-selling. Epson is trying to encourage this, pointing out that other  companies will exploit these opportunities. “If you are printing a customer’s business cards then why wouldn't you also offer to do their signage and corporate wear?”

companies will exploit these opportunities. “If you are printing a customer’s business cards then why wouldn't you also offer to do their signage and corporate wear?”

But then, how do you define the garments and home furnishings markets. Clearly, it’s a rare sign maker/wide-format PSP that’s going to be be printing thousands of dresses - but there is perhaps more scope for corporate wear, particularly T-shirts or jackets with company logos, as well as sportswear for local schools etc. Equally, the furnishings market can include everything from high volume bedding to personalised cushions, wall hangings etc.

Which technology?

Plenty of PSPs use solvent printers to print to textiles with quite acceptable results for short-term outdoor signage and interior wall hangings. There's a good range of canvas, flags and other substrates available from suppliers such as Spandex and Metamark with suitable coatings with no further investment needed for finishing.

And HP has consciously targeted the textile market with its latex printers, designing its Latex 360 printer with a removable top platen specifically for coping with textile printing. HP also sells a range of latex-suitable media, and has recently launched a new textile as an alternative to PVC for banners and displays, HP Light Fabric. It’s a 100% knitted polyester fabric that HP says offers good colour gamut.

But should you be looking at dye-sublimation? McMullin for one argues the case, saying: “If you are printing with dye-sublimation you tend to get a much higher impact because of the vibrancy of the inks when they go through a heat transfer process, which is much better than on an eco-solvent.”

Exhibition graphics is a particularly suitable application for dye-sublimation printing, As McMullin points out: “It's ideal where you want to have a really high quality photograph with punchy colours as a backdrop or as a curtain to separate parts of the stand.” Other popular applications include cafe awnings, umbrellas and branded deckchairs and there is some scope for printing textile building wraps, which is quite widespread in parts of Europe.

It's also worth noting that dye-sublimation printing can be used to produce promotional items such as mouse mats – not textiles as such, but they use polyester-based coatings and work on the same  principle.

principle.

There are several small desktop printers that cater to this market, mainly using flatbed UV printing, but Rob Goleniowski, business manager for Roland, says that “people that have looked at the flatbeds have come back to the due sublimation market.” He argues that this is because the bigger dye-sublimation printers can handle larger volumes.

Goleniowski says that only a small number of people look at the garments and furnishing market, noting: “There are some people that are dipping their toes in it with things like wallpaper. But you need a sewing machine and extra finishing equipment so there's an overall investment required that's been a barrier in the past.” But, he says that there is a renewed interest in dye-sublimation and the markets that it can open up for PSPs.

Of course your choice of printer depends on the type of print and the volumes that you anticipate working with. It might make perfect sense to start with a solvent or latex printer to determine if there is a market, before having to invest in hefty finishing equipment. But a dye-sublimation printer will ultimately give better quality results if textile printing is to be a major part of the business.

What's out there?

Leaving aside any solvent and latex printers, there are quite a few dye-sublimation printers that are suitable for graphics work.

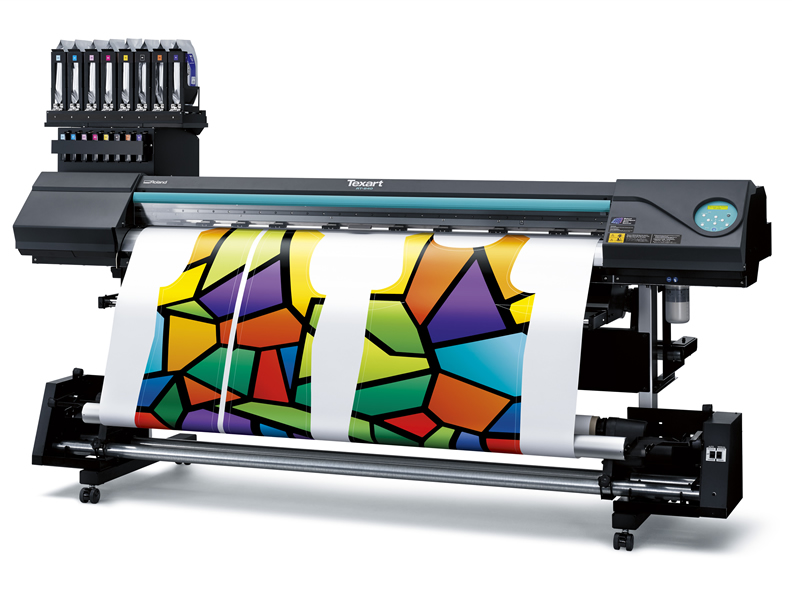

Roland has developed a new sublimation printer, the Texart RT-640, complete with its own inks. It has eight ink channels and can be set up with two sets of CMYK or eight colours including orange, violet and a strong black. There’s a choice of Rips between Roland’s own VersaWorks and a Roland edition of the ErgoSoft Rip.

Epson has a number of dye-sublimation printers, including the SC-F6000. This is a 44in wide roll-fed printer that’s capable of printing up to 720 x 1440dpi resolution onto transfer papers.

Epson also sells the SC-F2000, an affordable direct-to-garment printer that’s mainly designed for small items such as t-shirts and hats but can also do jackets and bags.

McMullin says that Epson is looking to extend its portfolio and that it does have a long term plan to develop a 3.2m wide printer to appeal more to graphics users.

Mimaki is one of the pioneers of textile printing and has several models. This includes the TX500DS, designed for volume users. It can run at up to 150m2/hr and is suitable for producing point-of-sale banners, lightboxes and flags. Mimaki also offers dye-sublimation inks for some of its solvent printers, including the JV300 and has its own latex printer, the JV400LX.

Durst, which also has quite a few textile printers in its offering, has just launched a new model, the Rhotex 180 TR. This is an industrial dye-sub transfer printer that is suitable for polyester and polyester blends. It’s a 1.8m wide machine capable of producing 200m2/hr and with a maximum resolution of 1200dpi. It uses a new water-based inks, which Durst says can be used without pre- and post-treatment of the textile fabric obviating the need to buy a washing machine.

Mtex has a number of textile printers that incorporate the fixation unit. It recently launched a the Vision printer. This is a 1.85m wide device that offers direct printing onto stretch fabrics with resolution up to 1200dpi. There’s a choice of four and eight colours. For now it comes with direct disperse inks for polyester but Mtex will later release a pigment ink set for poly cotton/natural fibre fabrics.

{jathumbnail off}