Richard Stuart-Turner takes a look at some of the technical developments that are likely to create the biggest impact in large-format in 2018.

While another politically turbulent year has rattled many industries and affected business confidence, large-format PSPs have maintained a relatively positive outlook. Around half of the respondents to our Widthwise 2017 survey said they felt confident about their business’s prospects wh=ile nearly four-fifths expected their wide-format sales to increase this year. But there is good reason for this optimism, and few signs to suggest that things will slow down as we move into 2018.

One of the most significant large-format launches of 2017 was Canon’s UVgel waterless ink technology, which is based on a UV curable ink that instantly gels on contact with a media. The first machine to incorporate this technology, the 1.6m-wide four-colour roll-to-roll Océ Colorado 1640, was launched earlier this year and Mark Lawn, director of the graphic and communications group at Canon Europe, says more will follow in 2018.

“We knew that the very essence of UVgel is that it would enable us to create a family of devices to facilitate a much broader range of applications. So we will extend the capability of UVgel into different products, initially in terms of size. We can safely say that when we get to Fespa [taking place in Berlin in May 2018] there will be some exciting developments in that arena.”

Lawn says Canon is also working on updates for its range of Océ Arizona UV flatbed printers. “We’re focusing a lot on the development of new applications and application capability. Some of that is enabled through software and workflow and some is enabled through modifications to the core technology of the machine.”

He highlights the new High Flow Vacuum system, which is said to make it easier to secure substrates that are difficult to get flat to the bed. “We’ve got a much higher suction to the bed which allows us to pull down and keep in place the media itself. We can deliver fantastic quality on top of that, which will take us into some really interesting areas such as corrugated and some of the packaging aspects associated with that.”

Lawn notes that one of the sector’s current major growth areas is what he calls ‘industrial’ print, particularly for interior décor applications such as wallcoverings.

“If you look at the personalisation of spaces, whether it’s in a home or office environment, it’s more and more what people and organisations want in order to reflect their brand identities and values and to be able to make spaces work more effectively for them.”

The latest manufacturer to enter the decoration market is Ricoh, which is set to start shipping its first UV flatbed printer, the Pro T7210, early in 2018. This machine can print at up to 50m2/hr in standard mode, or 100m2/hr in high-speed mode, and has a maximum print size of 2.1x3.2m. The device uses Ricoh’s own UV ink, which is said to have high adhesion properties for performance on a wide range of rigid industrial materials.

Ricoh Europe head of commercial inkjet business, Graham Kennedy, says: “The robust build of the Pro T7210 makes it ideal for building material and furniture decoration substrates. This means that materials such as wood, metal, glass and composite will be widely adopted. These are key markets where inkjet decoration can offer significant value.

“The Pro T7210 will allow us to better understand the specific needs of the industrial decoration market and align our future product development plans accordingly.”

“The Pro T7210 will allow us to better understand the specific needs of the industrial decoration market and align our future product development plans accordingly.” Frazer Chesterman and Marcus Timson, directors and co-founders of FM Brooks, have for years provided a platform to educate PSPs on the growing possibilities of industrial print with their InPrint event. The pair are also launching a new event, Pure Digital, which they say is designed to show creatives what can be achieved with innovative digitally printed applications. The inaugural show will run alongside construction exhibition Building Holland at the RAI in Amsterdam from 17-19 April 2018.

Chesterman, like so many others, recognises that it’s important for PSPs to get creatives on side in order to prosper in the future. “The market is currently steady - it’s flattened in terms of the sales of machinery and the sales of print and we think that the next stage to get a burst of growth is to start educating the end users,” he enthuses.

Another area that continues to offer a raft of new possibilities and added-value opportunities going into 2018 is the still flourishing digital textile printing sector. With Heimtextil set to take place in Frankfurt in January, we will look at the developments happening in this area at greater length in the next issue, but worth mentioning now is a newly launched Epson printer targeted primarily at this market.

The manufacturer debuted the SureColor SC-F9300 dye-sub printer at The Print Show in Telford in October. Phil McMullin, Epson UK sales manager for ProGraphics, says the 1.6m-wide machine is geared primarily for roll-to-roll production but that PSPs have also used the model it has replaced - the SC-F9200 - for printing onto rigid substrates.

“It’s the feed and take-up system that we’ve spent most of the time and effort on [improving]. It’s highly accurate – if you print onto a roll of paper and then put that onto your calender with a roll of textile, you’re going to get incredibly accurate results when you sublimate onto the textile. We’ve also added about 10m2/hr to the top speed so it’s up to about 109m2/hr now.”

McMullin says another of Epson’s main focuses going into 2018 is looking at how it can continue to enhance the colour gamut and the consistency of the reproduction across its entire portfolio.

“The drive for us is the same in all areas, which is to improve the productivity of our print engines without sacrificing quality, and in fact trying to improve quality at the same time. We’re spending on average about $1.5m a day in Japan on R&D and about half of that is on ink chemistry. That’s where we see as being the battleground going forwards - it’s where you can really score. I think my expectation is that we will start to see a raft of new products coming through at the end of 2018.”

Another manufacturer set to bring a number of new innovations to market in the next 12 months is Mimaki, which has just launched two new 1.6m-wide roll-to-roll LED UV printer/cutters, the seven-colour UCJV300-160 and the four-colour UCJV150-160.

Mimaki distributor Hybrid Services hosted the UK debut of the new machines at The Print Show in October. Brett Newman, chief operations manager at Hybrid Services, says the kit offers PSPs simpler routes into new sectors, such as the décor market.

“They’re a hugely appealing proposition; low running costs and great potential for producing highly creative applications appears to be a winning recipe.”

Mimaki’s current focus also lies in looking at some of the emerging trends of the future, many of which we have looked at in detail in our On the Radar features over the past 12 months.

“The Internet of Things and general connectivity enhancements are already present in a number of Mimaki’s print devices, enabling operators to communicate remotely with printers, benefit from smart diagnostics tools and receive instant messages from the hardware,” says Newman.

“Automation is also in place and continues to be developed; integrated workflows that tap into industry standard software to reduce training time and offer familiar workspaces, intelligent firmware that communicates with the operator and even barcode data that contains print and cut job instructions to ensure output is correctly oriented to avoid have all been implemented, reducing waste, minimising downtime and increasing productivity.”

Newman believes there are also opportunities for PSPs in augmented reality. “There is strong creative potential in this area and working with augmented reality could help print companies have a positive impact on direct marketing, retail and event signage that incorporates the technology to deliver a more personal and interactive experience for the user.”

Inca Digital chief executive John Mills says similar technology could also be used by manufacturers to help them to explain the benefits and features of their new machinery to customers.

“One of our competitors at SGIA didn’t have a machine at the show but they had a virtual reality booth and with that you could ‘walk around’ the machine. This helps customers to understand the technology.”

Inca will be placing much of its 2018 focus on its new Onset M B1 inkjet printer. This machine uses UV-cured ink though Mills says there are plans to release variants over the coming years to suit different needs.

“Some industries will want water-based ink, for example, so we’ll have a machine for that though it will probably be around 18 months to two years away.”

Inca's other current major focus is on automation, particularly for its Onset X series of flatbeds, which Mills says are now available with various robot options.

“The top speed of the Onset X3 is 225 beds per hour - there aren't many people that need to go any faster than that for POP, what they need is more flexibility and to be able to do more things with it. The automation systems that now come with the Onsets, as well as the software to schedule work through the machine, make it easier to get [work] from pre-press into the machine. This is all helping the machine's throughput.

“And the multiple robot options add extra flexibility because the robot can place the substrate wherever - onto a stack, a cutting table or a conveyor. And it places it more accurately, which increases your finishing options and can also give you a higher stack height.”

But Mills notes that the necessity for a robot is typically dependent on a printer's productivity. “If you buy a machine that can only print 20 beds an hour then the operator is only having to do something every three minutes so a robot might be a relatively expensive solution.”

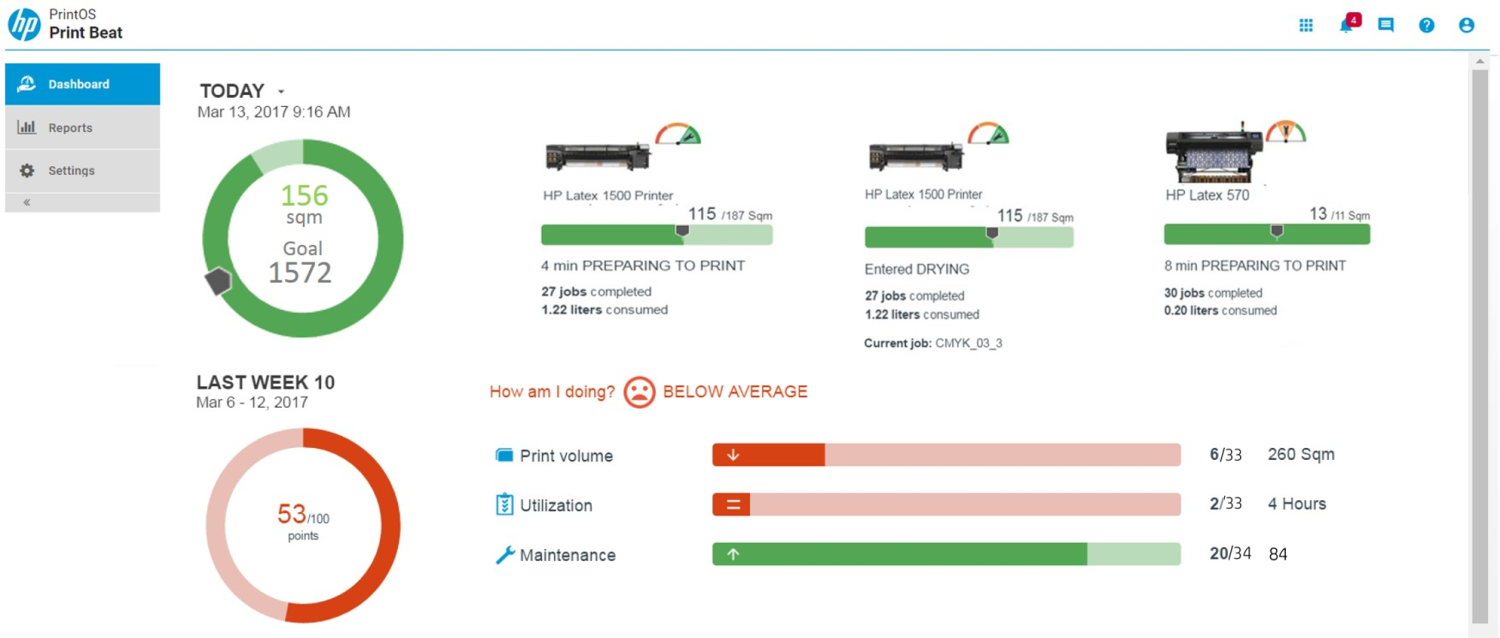

One of the areas of workflow automation that looks set to be increasingly adopted by large-format PSPs over the next few years is the use of performance dashboards. These provide users with real-time information about their printer, or any number of printers, linked to the dashboard and can help them to manage jobs and assess the operational efficiency of their machinery, indicate the profitability of each job and highlight any issues or potential problems that could arise.

At Fespa 2017 Durst launched a new software offering of this kind, Durst Analytics. The manufacturer says this is a preventive service option that guarantees user uptime by monitoring machine parameters and taking proactive service measures.

At the same show, HP announced that it was expanding its PrintOS cloud-based operating system, which simplifies and automates print production, to include Latex and Scitex large-format machinery.

“Workflow automation is pertinent right now and we're putting a lot of emphasis on this,” says Mike Horsten, HP Graphics Solutions Business EMEA sales manager for large-format graphic production.

“PrintOS came from the Indigo side, the larger printers where an operator would like to look at what is happening with their machines and have a bit more control. In one location remotely we can now address what's going on with the printer, see where the errors are, pre-empt errors, look at production speeds and much more.”

Horsten says PrintOS is a scalable operating system that enables multiple HP printers to be viewed on the same Print Beat dashboard. PrintOS currently supports the high-volume industrial Latex printers though HP says it is working on support for the 300 series and 100 series models.

The manufacturer has just launched a new addition to its Latex 100 family, the entry-level Latex 115. This 1.4m-wide machine is available as either a standalone printer or as a print and cut package.

“We will continue to expand in the Latex arena - we will look at new applications and different areas. We've started into decoration, we're looking into soft signage and we'll look into home textiles - things like curtains and bedspreads,” says Horsten.

As we move into 2018, it's clear that all of the manufacturers are now looking at the bigger picture and considering how they can capitalise on the opportunities that new and emerging technologies will bring to the large-format sector, how they can help PSPs to reap the benefits, and how they can reap bigger benefits themselves from sectors perhaps beyond this readership’s ken (see What They Say features).