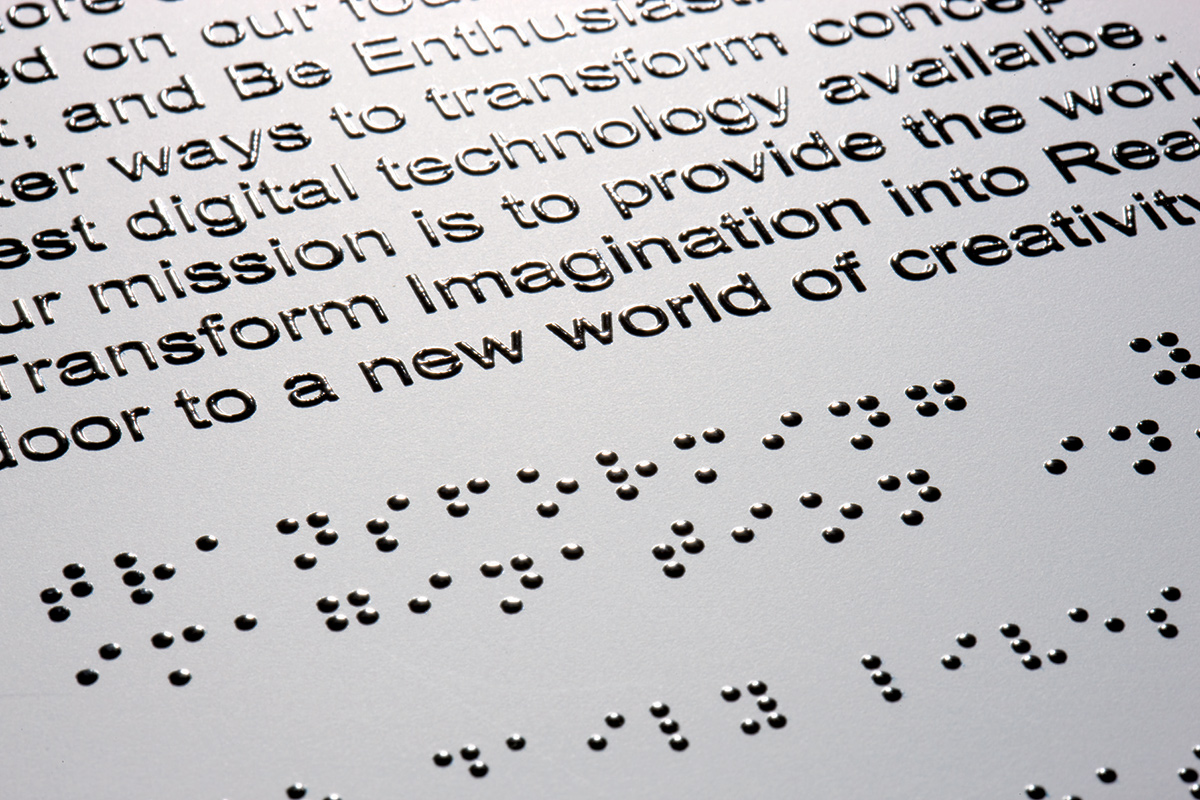

Today’s UV inkjet technologies offer all sorts of niche applications and it seems there’s a growing demand for Braille - and other tactile print. So is it something you should be investigating?

In the UK alone there are over two million people with a sight problem, and tens of thousands use Braille. Back in 1995 the government passed the DDA Act, and in 2010 the Equality Act, which clearly state that businesses and organisations must make ‘reasonable adjustments’ to ensure that, among other things, they provide well-defined Braille and tactile signs for the visually impaired. According to Keith Pratt, director of Atlantic Technical Services, PSPs with UV inkjet capability are starting to realise the opportunity that affords them.

“As the UK distributor of Azon UV printers we have seen a marked increase in the demand for machines to produce high quality Braille print results,” says Pratt, pointing out that the “Azon Razor and the larger Matrix range of UV printers are designed to meet the high quality demands of specialist markets such the production of ADA compliant and or Braille script and signage.

“The Azon UV inks produce excellent adhesion, particularly when printing multiple layers in the production of the raised dots for Braille signage,” he says. “Many of our potential customers are asking us to produce samples of Braille text and to explain the capabilities of the Azon printer range in this area, and there has been an increase in our existing Azon printer users wanting additional training to produce this type of work to meet with an increasing demand.”

The Azon printers - together with the Azon Rip software - can print up to five layers in inline mode, dependant on resolution, fading and changing the number of used nozzles, to create embossed or raised print up to 2mm and thus enabling users to print regulation-meeting Braille.

“Creating embossed or raised print up to 2mm decreases the need for specialist software such as Illustrator, CorelDraw, Photoshop etc.,” explains Pratt. “The Azon Rip allows users to instantly choose the proper settings for their applications, which dramatically increases the printer’s productivity and overall performance and print quality.”

Pratt isn’t the only UV printer supplier noticing the increasing demand from PSPs for machines that can produce Braille and other raised print applications.

“Tactile signage is a growing market and it makes an excellent add-on to your product catalogue, provided you have the tools in place to produce it,” says Rob Goleniowski, head of sales - UK and Ireland, Roland DG.

“We see lots of customers looking to diversify their business and offer a wider range of products and services - after all, if your competition is investing in growing their business, you’ll need to improve your offering too if you want to maintain your edge. The ability to print Braille can be a great differentiator, but it’s important to think beyond a single application and open your mind to other potential printed products.

“How can you justify buying new equipment simply to create a single application? It’s easy to see that as a challenge, but it’s actually a great opportunity - with the right equipment, you can expand your capabilities well beyond Braille alone.

“The biggest challenge is cutting down the production time and finding the most efficient process that works for your business. At Roland, we offer two main solutions for those wishing to produce Braille signage - UV printing and engraving. Besides letting you easily print Braille, both of these technologies can be used to create a huge range of other products too.”

In a quick reference to the engraving option, Goleniowski steers you to the company’s EGX engravers, “which have proven to be a popular choice for creating tactile signage”. He adds: “There are two main methods of creating Braille signage with an engraver - users can either drill holes into which Braille beads are installed, or they can cut the shapes using a specifically designed cutting tool. With very different steps in the set-up process when compared to UV printing, the result is a hard-wearing, tamper-proof piece of tactile signage.

But for most of you, UV printing is the more obvious route to producing Braille - and maximising printer investment.

“Our UV printing technologies can be used to print onto virtually any object. Aside from the breadth of applications made possible with CMYK UV ink, our gloss ink unlocks even more possibilities. This ink can be printed in layers to achieve tactile effects and 3D textures, making it an ideal solution for high-volume Braille applications. These machines range in size from our benchtop VersaUV LEF-12i UV printer, to our wide-format S-Series, and can be used to print Braille directly onto signage or packaging,” says Goleniowski.

Over at Mimaki UK distributor Hybrid Services, chief operations manager Brett Newman, offers the reminder that Braille can be printed in either process colour or clear ink, resulting in either a visual cue for partially sighted users, or, for example, applications such as medical packaging, where a clear Braille print is applied to the carton so that there is no interruption of the main printed message.

“Mimaki’s flatbed LED UV printers are capable of producing Braille thanks to the high quality of registration afforded by the hardware, the instant curing of the ink and the ability to accurately build up multiple layers of ink in order to create a raised print,’ enthuses Newman, pointing out that Mimaki’s UJF printers range in size from the UJF-3042 (which has an A3 bed) up to the UJF-7151plus that sports a 710mm x 510mm print area. With the ability to print up to 150mm thick objects on some of the models, Braille can be applied to rigid items, boxes and structures.

“New developments in Mimaki’s RasterLink6 Plus software means highly accurate Braille printing is achievable, as additional software tools ensure the design process is seamless, enabling characters to be created within standard design authoring packages.

“As a result, Braille is created using Mimaki’s LH-100 clear and primer by setting a spot colour around Braille characters in Adobe Illustrator using RasterLink tools. Compatible with the UJF series LED UV flatbed printers, a wide array of Braille applications, such as signage and wall plaques can be created to allow visually impaired people to be independent and engage in public spaces with the reassurance of legible wayfinding or safety signage. This is an important area for the sign and graphics industry, as in the UK alone, there are almost two million people living with sight loss and thousands registered as blind or partially sighted.”

Braille - or any type of tactile print - is hardly likely to be your number one reason for investing in UV print technology, but given that so many of you are buying the kit anyway, you’ve got to wonder if it’s an option worth exploring. Those with vision probably already are.