Sampling has become a crucial part of applications R+D, so are you getting the help you need from media suppliers? Soyang Europe sales director, Andrew Simmons talks about what it is doing to this end.

Why is it not a more common occurrence for media suppliers to offer a printed sampling service? After all, the more they can convince you that their product can help you develop profitable new offerings, the more they grow their own bottom line. It’s an argument that is starting to catch on.

Take Soyang Europe, with its mantra of having ‘Every Surface Covered’. According to sales director, Andrew Simmons, that means making sure customers can fully investigate its full range of media as thoroughly as possible.

“Our portfolio is comprised of Soyang’s Far Eastern manufactured textiles and PVC products which sit alongside European and US manufactured wallcoverings, floorcoverings, self-adhesive vinyl, further textile ranges and other speciality media, so it covers a substantial gamut of applications. Talking with our customers, we know the value of them seeing the materials before they buy, but very often, a printed sample can tell a much more interesting story - and one that’s easier to comprehend.”

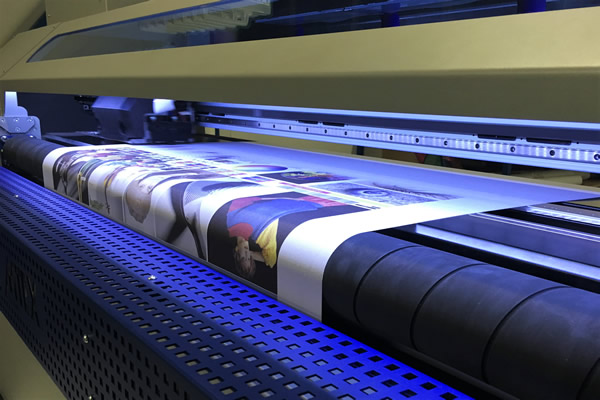

Soyang has invested in print kit to allow it to offer a printed media sampling service, as Simmons explains. “We first installed a wide-format printer a couple of years ago, with a Mimaki solvent machine purchased to provide samples on self-adhesive vinyl, banner and display materials. We’ve since added HP latex printing capabilities and now, with the recent acquisition of the MTEX Blue Dye Sub model, we’re able to replicate almost all the technologies our customers use in the field. Our sample room also includes hardware to slit rolls down, as well as quality check batches so we’re well prepared for any eventuality. Once they’re using the media, we’ve got the capability to help our customers with tech support too.”

The Soyang Europe range has evolved consistently and now includes media sourced and developed with the express intention of helping PSPs add margin. “We understand that - especially on the grand-format printers - there’s a need to pay back considerable capital investment in the hardware, and to do that the machines need to be worked hard. Whilst we’ll just as happily supply a substrate such as a banner or mesh that will make the PSP a good margin, putting something more ‘interesting’ on the printer could potentially yield far more income in a far shorter time.

“This has been a key factor in the success of products like G-Floor, our LED UV printable clear floor covering which has taken retail, public space decoration and the exhibition sector by storm. We’re fortunate to work with extremely imaginative and creative printing companies, but even for them, seeing a printed sample tends to be crucial to fully grasping a product’s potential and appreciating its point of difference,” says Simmons.

Much as a 500mm square of unprinted clear 3mm thick PVC could feasibly be ‘just another media’, so the same applies to textiles, if not more so given that colour yield, handle and finish can alter so much when ink is applied to the latter. So providing printed examples is proving to be a vital sales tool at Soyang. “Our sales managers are even equipped with small portable lightboxes so they can demonstrate products such as our Impact Prime backlit in-situ,” enthuses Simmons. “Very often it really is the case that seeing is believing!”

He adds: “Where a media exhibits major benefits over alternatives, it’s far better to be able to show this in its printed form to prospective customers as well - and leaving printed samples with them can assist the sales process they go through with their clients too. It’s one thing us talking with well-educated print companies who understand the broad concept of the products we can offer, but making their life easier when in discussion with the end client who is commissioning the job is proving enormously beneficial too.

“Really, it all comes down to making life easier for our customers and using technology to facilitate both our and our customers’ sales processes. With this in mind, one of the big benefits we’ve seen already is that it cuts down our sales lead-time. It’s fairly standard practice to send out a roll of media for customers to test on their own machines and of course, this has its advantages, but the pitfalls lie with how busy our customers often are. If they’ve seen a printed sample produced on a similar machine with similar ink chemistry to what they’re using, it’s only a small leap of faith to know it’s going to work for them too.”