…as to what’s happening on the digital inkjet inks front. Some of what Simon Creasy hears may surprise you…

Historically, when a PSP looked to buy a new piece of kit, the sales pitch would focus on the hardware’s capabilities. The sales patter would usually run along the lines of: “The machine is capable of printing at X sheets a minute, it can handle X type of stock and the quality is better than anything else on the market.” If ink was mentioned at all it would usually be as an afterthought or as part of the conversation surrounding total cost of ownership. Times have changed.

Press manufacturers have recognised that there is only so much you can do with a printhead to enhance performance and the marginal gains achieved on the latest generation of heads are getting ever more marginal. The rest of the performance enhancement and the reduction in the total cost of ownership for the end user has to come from ink and the way it performs when it hits the substrate. That’s why a number of leading manufacturers are focusing a lot of time, money and R&D effort to devise new ink sets for their large-format printers.

One company that’s really pushing on this front at the moment is Epson. According to Phil McMullin, UK sales manager for pro graphics, the company spends about $1.5m a day on R&D across the corporation and a “big chunk of that is on ink chemistry because ultimately along with our piezo head, that is what differentiates us from other players in the market”.

McMullin says the company’s “armoury” of ink sets covers a vast gamut from water-based ink through to dye-sublimation. One interesting trend he has detected in the last 12 months or so in the ink space is PSPs switching from resin or latex ink to eco-solvent.

“I’ve been in the industry for about 18 years and certainly for the last decade and maybe slightly longer the trend was to claim solvent was dead and resin or latex was the future. However, what we’ve seen over the last 12 months is a re-adoption of eco solvent.”

McMullin explains that the current range of eco solvent ink offered by Epson - which are certified by Greenguard - have had all of the carcinogens and nickel taken out so many of the concerns about solvent inks have been assuaged.

“Once people have realised that the environmental credentials of eco solvent are pretty solid they’ve looked at the vibrancy of prints you get with that inkset compared to a resin or latex inkset, and they’ve looked at the much wider array of media you can print onto because you’re using a much lower temperature on the platen,” says McMullin.

“You’re also looking at about 15% less ink going down so you’ve immediately got a saving of 15% for a better image quality and the price of the ink is about 15-20% lower as well. If you put that together you’ve suddenly got a compelling argument as to why it’s worth looking at the technology and reaping the rewards of a lower running cost pretty much immediately.”

He adds that digital PSPs are coming back in large numbers to this “older technology’” and to emphasise his point he says the company has seen sales growth of 60% this year for its UltraChrome GS3 ink set and he anticipates this trend will continue.

Another ‘older’ ink set that appears to be performing well at the moment is UV. It’s a particular area of focus for Fujifilm, which recently launched Uvijet OX - a high adhesion ink for the company’s Onset platform that has been specifically developed for rigid plastic media at the fastest multi-pass print speeds.

Andrew Berritt, marketing manager, Fujifilm Speciality Ink Systems, describes the ink as a “real leap in technology” for the company. He adds that the reception from the market to the Uvijet OX has been very positive.

“UV ink has started to be perceived as ‘old’ technology, as other print technologies are being more aggressively marketed,” says Berritt. “But the fact is, UV ink technology remains the ideal solution for many applications and as printers and printing equipment evolve, the ink systems need to as well.”

Canon is also pushing on the UV front with the Océ Colorado 1650, which launched at Fespa Global this year, and is the latest addition to the UVgel family. According to Duncan Smith, county director for production printing product at Canon UK, it offers flexible inks and Océ FLXfinish with a matte or gloss finish, without changing inks or media, as well as double-sided printing.

“This means customers can print on a wider range of SAV media, and the matte option gives more opportunities in the interior décor market,” says Smith. “We designed the product as a clear response to evolving requirements for new applications. After the success of the Colorado 1640 model - which also offers proven UVgel advantages - we identified further opportunities with customers that prefer a matte finish and a more flexible ink.”

Smith adds that through the company’s UVgel inks which “push the boundaries of innovation, Canon is meeting a strong need on the market from customers seeking to differentiate their print offering. Inks that can offer breakthrough productivity, low TCO and a wide choice of applications - with both matte and gloss finishes - will continue to be in demand from customers”.

These are the same guiding principles used by Kornit, whose latest pigment ink set is Neopigment Robusto. “This ink was developed to last and has better wash and rub durability ideal for baby, DIY, and fashion industries,” explains Sharon Donovich, project manager for Kornit Allegro direct-to-fabric print system. “It has high UV fastness that enables extended outdoor exposure, perfect for home décor applications. It answers the highest industry demands with a wide variety of fabric types and an extended application range. This ink has increased colour gamut, volume, and spot colours coverage. It Improves productivity and maintain the highest market standards.”

Donovich says customer reaction to the new range has been very positive. “Both new and existing customers find this product a huge improvement on the previous version and the opportunities with this product are much larger. According to customers, the new Robusto ink demonstrates enhanced colour fastness properties and a continued focus on low impact coloration.”

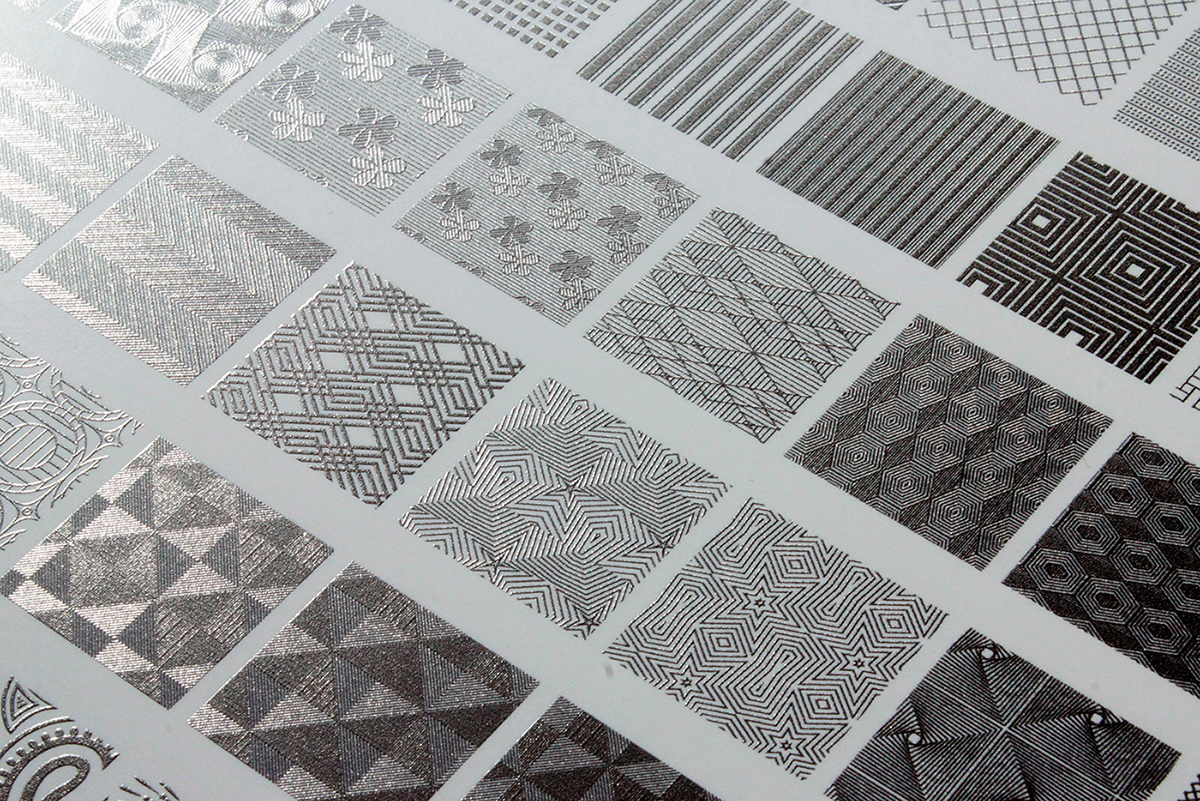

Over at Hybrid Services, exclusive UK and Ireland distributor for Mimaki, Brett Newman, chief operations manager, says that one of the most exciting additions to the company’s own range of inks is a new metallic LED UV ink, designed for Mimaki’s UJF-7151plus mid-format flatbed printer.

“The world’s first metallic UV ink is created by mixing a bright pigment into the ink, resulting in the ability to directly print without the need for a separate manual transfer process, as is the case when applying glitters or foils to produce a metallic effect,” explains Newman.

He says decorative options such as printing both gloss and matte tones, texture expression with embossing effects, and full-colour metallic expressions can be achieved by printing coloured ink overlaid on the metallic ink.

“This revolutionary new ink expands the creative horizons for our customers, enabling them to offer increasingly premium printed products that can deliver maximum revenue potential,” adds Newman. “Mimaki’s metallic ink design achieves the maximum amount of light reflection by placing pigment particles flat against each other once cured, giving a really shiny effect and a uniform finish.”

He says customers are always looking for new “ways to diversify, add value and create desire and want from their customers” and Mimaki’s metallic ink has really hit this sweet spot in this regard.

While equipment and ink manufacturers are happy to talk up the latest additions to their product ranges, most are understandably coy about where their future NPD efforts in the ink space lie. McMullin says that going forward Epson has lots of NPD in the pipeline, both around hardware and inks, following a hiatus of a couple of years when the company didn’t introduce much new technology to the market.

“You’re going to see a plethora of products coming from Epson over the next 18 months to two years which will cover all of the different ink sets in application spaces you’ve never seen us play in before so it is an exciting time for us.”

He anticipates developments in numerous different areas, including UV. “The challenge with UV has always been its flexibility. If you’re trying to put it on a vehicle, for instance, you will have trouble printing onto a self-adhesive vinyl and then wrapping the vehicle with that vinyl because the ink will probably crack off. We’ve taken that on board and the guys in Japan are working on UV inks that are much more flexible.”

Another area the company is focusing its R&D efforts on is dye-sublimation. “What the end users are looking for is improved colour gamut, so we will be developing inks in that direction and also we will have additional colours coming out - spot colours, fluorescent colours, light colours so you can use that in production for photographic reproduction of images.

“Personalisation is the buzzword in the industry and people want to reproduce anything they have photographed or painted on rigid media, or on textiles, exactly as they’ve envisaged it, so the ink needs to be at a better level to perform to people’s expectations and you will see that from Epson coming down the line as well.”

As for Fujifilm, Berritt says the company is “regularly looking at the altering legislation and requirements to ensure global compliance and helping our customers print into more applications - food packaging being an important example”.

EFI also has one eye on the legislative landscape and is particularly keen to develop inksets that are more environmentally friendly. “We’re always looking for greener solutions,” says Mark Goodearl, product manager - display graphics, at EFI. “The consensus is everyone wants a greener solution, but they don’t want to pay a premium for it. We’ve been working in that direction and with the low power consumption and other benefits that LED has brought to the table we are moving in a greener direction.”

The big issue for EFI and rival manufacturers of late has been the rising cost of raw materials, which is having an impact on their operations. Goodearl says that despite the economies of scale that a company as large as EFI enjoys it has been challenging to deal with the rising price of raw materials across the globe.

It’s a scenario that’s all too familiar to Fujifilm. “The cost of production has increased and violently fluctuated over the past 12-18 months,” says Berritt. “This is mainly due to global raw material shortages of specific key components. This has certainly had an impact on our business as we’ve been hesitant to pass on these drastic increases to our customers as they would be very challenging to manage.”

Raw material cost increase concerns aside, the roadmap for future ink development looks pretty exciting. With each new printer launched being successively quicker than the previous generation and with customers demanding increased print quality at these new high speeds, equipment and ink manufacturers seem to have finally started to recognise that ink has a greater role to play than perhaps at any time in the industry’s history.