Some things you can’t work with, and some you can’t work without. Here, print chiefs identify the kit/systems that have proven most crucial to their businesses in these times of flux.

Given the difficult trading circumstances and strategic decisions many have made to enter new markets, become more efficient businesses etc., we asked a number of large-format PSPs to identify the key kit/software helping them remain competitive. For some it was as if they’d been asked to identify their favourite child, for others it was a much easier call - either way, here’s what they chose to reveal…

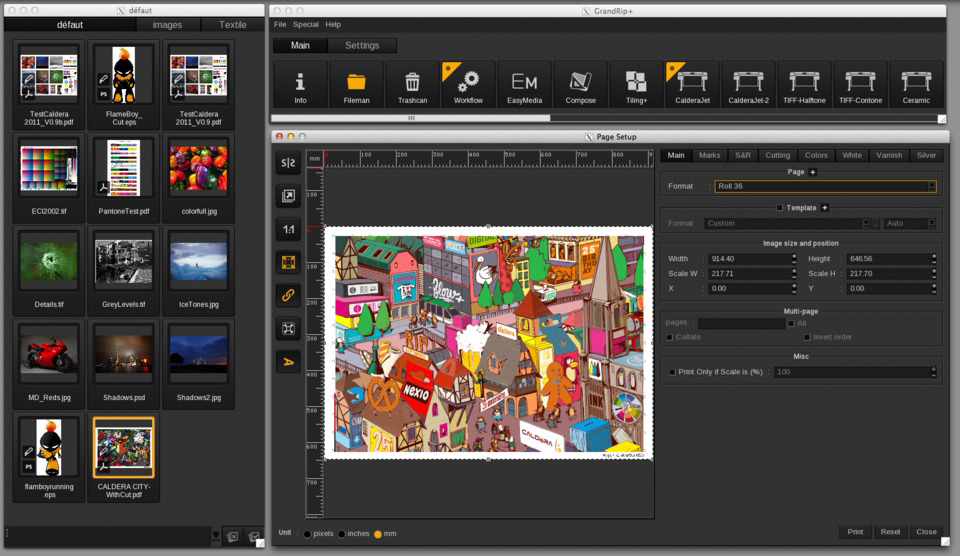

The Big Display Company

Jack Murphy, marketing director

Caldera is the heart of our production department. We were at the stage early last year where we were running several different Rips across several different machines, and setting up all of our artworks manually - using third party software for layouts. This was time consuming in pre-press and resulted in mistakes by human error, which added extra strain on our production department.

It was early on in the pandemic when we started looking at cost savings and efficiency improvements, and after a lot of research we decided to implement Caldera for all of our printers (UV, dye sub, latex and aqueous). We connected our Zund and our Summa cutters to Caldera and we immediately reaped the benefits. Each file is set up in pre-press as a ‘1-up’ file and the machine operators now create their own layouts at the point of printing, using the most economical size sheets and rolls as well as combining multiple jobs on the same print runs.

The time savings in pre-press, the reduction in mistakes and the material savings from clever layouts more than paid for the software within a couple of months.

We now have a much more streamlined process, and far fewer headaches. Print operators can work quicker because they’re not having to use several different softwares at the same time. These savings and efficiency improvements have been crucial in our survival throughout the pandemic, because it means we continue to be competitive in an increasingly difficult market, but still reach the impossible deadlines that we’re so used to working to.

Data Image

Rob Farfort, founder and CEO

During the pandemic, with both furlough and home working impacting the daily operation here at Data Image Group, the roboticised Esko Kongsberg C66 came into its own.

The benefit of an automated cutting system means it can be left to run remotely, and it was programmed to work alone, even overnight, to turnover projects in a short space of time whilst we as a business were able to comply with social distancing and ensure a safe working environment for the team.

One of the highlights of the Esko robot came at the height of the pandemic and the PPE shortage in 2020. At that point we used it to produce over 1,000 PPE face shields for key workers as part of our not-for profit PPE initiative, which saw £1,000 donated to the Child Bereavement UK charity.

Ebbsfleet Print Solutions

Sam Cherry, owner

Our favourite bit of kit is the Summa f1612 flatbed cutter. We invested in the Summa F series with Adam Booth [of RA Smart] in 2019 and we haven’t looked back. It’s used every day and not only allows us to free what were print finishing bottlenecks, but to offer our customers diverse solutions like mock-up stands, packaging and high end labels.

Having a Summa F1612 is like having two additional members of staff that we don’t need to pay!

MacroArt

Matt Guise, sales director

Over the last year we have been working on improving client interaction and refining our communication with customers. While adapting to the ever-changing situation, we’ve been working hard on implementing new software solutions to enable us to support our clients from point of enquiry through our studio, production and despatch departments.

Our new ERP and prepress workflow solution work together to dramatically speed up the process of getting artwork into our studio and proofs ready for customer approval. As well as improving our existing service, we are now able to offer an individual client portal, which will enable each customer to view recent orders, approve artwork and place new orders directly into the system from a set of tailored products created specifically for each of them.

All of this progress means that we are now able to process customers’ orders more efficiently and effectively, reducing potential errors during transfer of information and increasing the speed in which we can process orders.

We believe these new solutions will offer far more than any others on the market and represent great benefits for both MacroArt and our customers.

Quarmby Colour

Damian Quarmby, owner

Thankfully we are still chugging away with pre-Covid contract work, and whilst we have many great pieces of kit the true shining star so far has to be the EFI Vutek H5.

It really is a game changer in terms of versatility, productivity and reliability. To my mind it’s the best printer you can have as a PSP in the large-format industry!

Signs Express Nottingham

Mikey Walker, workshop and fabrications manager

We have been growing consistently over the past few years, and have doubled our team to handle the growth in the business - positive news in very difficult and demanding times. I firmly believe that a contributing factor to our growth is that we have upgraded to a new larger-format printer - the amazing Epson S80600.

We upgraded from a Roland 540 smaller bed printer as we always struggled to print things that would fit on larger panels - we would have to print in two parts and have joins on panels.

Since the upgrade, we have been able to expand into more sectors. I believe that advertising is becoming an ever growing market and people want the biggest signs to advertise their businesses, especially now they are planning to re-open from the lockdown.

We can now print full panels and also larger window graphics amongst many other things.

Particularly when printing wallpapers and wall graphics the wider-format now enables us to produce less drops and therefore have a more professionally and high quality finish and save time.

Also, having a larger heating bed has helped - it enables us to dry the printed media faster and as such is making our production far more efficient.

The maintenance functions built in work a treat too. Head cleaning, parts maintenance and plenty more is now so much easier than it ever was before

Solopress

Simon Cooper, MD

The large-format kit we’re most grateful to have on board at the moment are our Agfa Anapurna H2500i LED presses.

Large-format has been a huge growth area for Solopress in recent times, with production increasing at a rate of 30% year-on-year. It was this increase that led us to invest in two of these Agfa Anapurna machines back in May 2019.

Having previously produced on roll-to-roll Inktec Jetrix RX3200s, the new Agfa 5m hybrid presses allowed us to diversify, both in terms of the materials we could print on and the product range we could offer.

As fate would have it, this functionality would prove crucial. As the pandemic took hold, we were able to pivot production towards clear screen roller banners, hand sanitiser stations, social distancing signage and other coronavirus essentials. With other areas of the market suppressed, these streams brought in essential revenue for us during 2020.

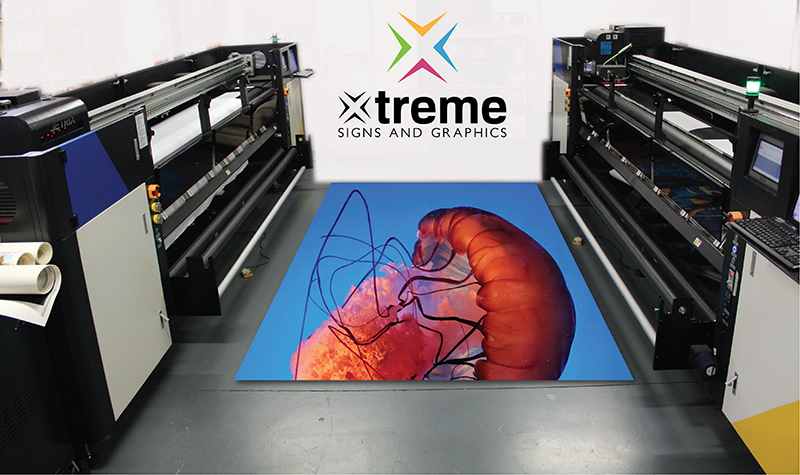

Xtreme Signs and Graphics

Pierre Pheiffer, owner

At Xtreme Signs and Graphics we feel that our two 3.2m Jetrix UV roll-to-roll printers and our Comagrav cutting/routing table give us an advantage over others in the industry. The printers give us the ability to print large volumes of work in much smaller timeframes, and the cutting table has the same impact on finishing times.

In the current climate, we feel it is very crucial that the turnaround times on jobs are as fast as possible, and that goes hand-in-hand with the quality of the product and the price that we can supply the product to our customers. We are constantly trying to get new trade clients that might not have the same resources to become trade partners with us and investing in the kit that we have has definitely made this process easier.

MPH Enterprises

Simon Wilcox, marketing and production

technology manager

Firstly, a bit of background - MPH and Personalised Luggage are sister companies and are specialists in the promotional marketplace and the digital decoration of luggage and travel accessories respectively. Our production platforms are based on HP SiteFlow technologies.

HP SiteFlow was born out of product developed in the UK by OneFlow Systems and is one of the core tech platforms that provides an infrastructure for the on-demand and personalisation printing industry and underpins HP’s global Indigo and PSP network. For those of you who aren’t familiar with it, its job is to create structured workflows for importing, preparing (pre-press), aggregating, imposing, batching, scheduling, routing and managing digital print jobs (across all production technologies). And, dynamically passing the order status and information back to the ecommerce and shipping gateways.

So why couldn’t we live without it throughout the last year or so? The volumes for the MPH, Personalised Luggage and ThePersonalisedEdit businesses of digitally printed personalised and customised products have been enormous and growing rapidly. Without SiteFlow we’d be working back in the dark ages with Excel spreadsheets, manually created artwork, Post-It notes and a wing and a prayer! We can add new dropship clients and products quickly and easily into the production workflow without causing major disruptions. And, most importantly monitor each job and production line and see where the bottlenecks are before they become a problem.