Can wide-format printers in our sector make the most of the boom in demand when it comes to digitally printed textiles? Melony Rocque-Hewitt investigates.

The textile and apparel market is in love big time with digital printing and it’s serious. By 2015 the textile and apparel global market is forecast to be worth somewhere in the region of $1,557.1 billion, an increase of 32.5% since 2010. There seems to be little doubt that where the printing of textiles is concerned digital will be the future.

It seems that timing has a great deal to do with this particular love affair. Significant advances in hardware performance and speeds, inks and materials have finally come together making digital production for textiles viable, resulting in a seemingly insatiable desire for original, one-offs that have the all important affordability factor.

The fact is when it comes to digital textile printing, business is definitely booming. Jos Bastiaans of the Netherlands-based Print Unlimited confirms that his company has seen unprecedented demand for its textile printing with, for example, a 500% rise in demand for its home décor work – an area that accounts for 20% of his business which, in the main, outputs on-demand, digital print for the fashion industry.

So how can companies in the graphic arts sector make a play for a piece of textile action?

In the annual wide-format report Widthwise published by this magazine, of the 200 companies this polled year, 61.8% said moving into new market areas was high priority with retail, POP and POS the main focus. Just over 50% of respondents said they expected to buy a new wide-format printer in the next two years with 37.4% and 35.4% opting for latex and UV flatbed technology respectively. Only 8.1% said they would be investing in a dedicated textile printer.

Temporary textile printing - that is, using textiles as substrates for signage and display materials - is a fast-growing market well suited to those working in sign and display production.

“For most PSPs with UV or HP latex ink printers, the move to textile printing will primarily be a matter of substituting textile substrates for their current PVC, vinyl and paper,” explains Rut Quindos, sign and display production market development manager, EMEA, HP. “Typically, PSPs will be interested primarily in signage applications, including banners and flags, for their textile offering. However, their market is potentially much bigger if they explore the non-signage opportunities as well.” These sectors include furnishing and interior décor – premium products that act as a differentiator.

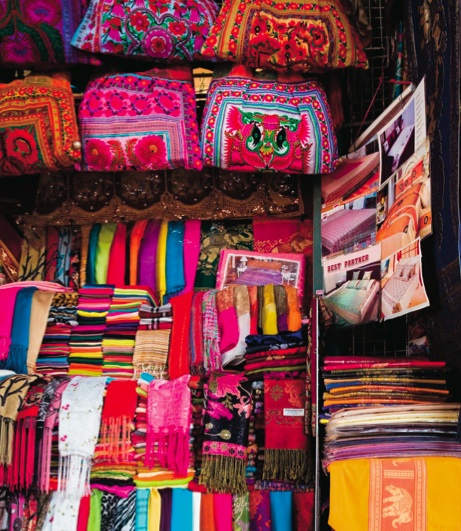

Other possible areas for textile printing are another step away from most PSPs normal work, but offer lucrative opportunities to develop specialist skills. The apparel, or garment, and accessories sector has a wide range of possibilities for printing fabrics for clothing, including scarves, ties, swimwear and other high-margin products. Then there is the area of speciality fabric printing that encompasses such diverse applications as automotive fabrics, medical textiles, protective clothing, sails and tents. While these sound like unfamiliar product offerings for a PSP, a fresh look at local businesses and industries could reveal new market niches.

One of the immediate benefits of using textiles is that they have distinct textures that can enhance graphics and provide a premium appearance.

“The first big reason for PSPs to add textile printing to their signage portfolios is that textile printing is not significantly different to what they are already doing,” says Quindos. “If they have HP latex or UV ink printers then the transition is straightforward: the printers are the same and your operators are already trained.

“There are still relatively few PSPs offering digital textile printing, so those that do not only offer a unique service, but can also enjoy the concomitant premium,” she adds.

London-based Coloursonic is a large-format print company which produces bespoke graphics, portable displays, exhibition graphics, hoarding displays, museum displays, glass manifestations, TV and film graphics, outdoor advertising, retail point of sale, vehicle branding, sign solutions, canvas printing and backlit displays for a variety of clients. Coloursonic invested in latex technology back March and according to director Michaela Chandler, while printing to textiles is by no means new to the company, the introduction of Latex technology has made what it does significantly faster and better.

Coloursonic is ever keen to innovate and is hungry to debut new materials and substrates to its wide client base. “We are 100% client driven,” says Chandler. “We go where our clients take us. New substrates are key because they spark the imagination of our clients, which in turn push the boundaries of what’s possible. Our investment in latex technology and our continual interest in new materials is about servicing our existing customer base to a much deeper level.”

Leaving latex aside – catching his clients’ imagination is something that Rick Jervis, sales director at The Image Group, has witnessed since installing a Mimaki dye-sublimation machine in-house almost two years ago.

Prior to that says Jervis, The Image Group was outsourcing its digital textile work. However, after installing a printer in-house, the company’s textile repertoire has expanded widely. Now in addition to flags, banners, internal signage and the like, the company is creating unique fabric PoS items, sofa covers, curtains, blinds, customized gazebos and carpet tiles for short term exhibition flooring work.

“Having a machine in-house has really focused us and allowed us to move into new areas that just wouldn’t have been as easy in the past. It has bought us flexibility and made us do things that we wouldn’t have considered before,” says Jervis.

Wide-format printing company Matic Media based in Lanarkshire is very much in the business of producing non-traditional print products amongst its daily sign and display offerings, but says MD Richard McCombe, central to its left of field vision are in-house skills such as software programming which makes the servicing of these new markets possible.

“Wide-format printing technology such as latex can produce a wide variety of non-traditional products,” he says, “but this is the tip of the iceberg. The problem for many wide-format printers is how they get their products to market. If they are targeting the consumer market the logistics of fulfillment and dealing with the public at large is a whole new ball game. Yes, it’s possible, but it’s a completely different business model and one that needs a good deal of investment and thought.”

Targeting the consumer market is an avenue that The Image Company is seriously looking into. Jervis has already looked at premises and says that this route will be a development for the company in the future.

The consumer market is a trail that already has been blazed by Reading-based wide-format printing company VGL that offers beautiful high quality wall hangings, murals, blinds; lampshades through its luxury interiors brand Printed Space. The company has pronounced that fabric is the future and has recently purchased a Du Pont Artistry textile printer.

The Kent-based ESP Group also clearly believes that the potential market for digitally printed textiles is substantial and to this end has installed a Hollanders HPS Colorboost XL. “Printing to polyesters and mixes has changed dramatically thanks to improvements in weave and finish of these fabrics, and it’s now easy to produce eye-catching displays that improve on visible impact,” says MD Stephen Hood. “The Hollanders solution enables us to generate new types of branding application on light-weight materials without compromising on quality.”

Textile printing can offer rich rewards and for PSPs in our sector to get into the running Jos Bastiaans at Print Unlimited says companies need to ask themselves where do I want to be in five years time? When they have answered that question, the next task is to devise a comprehensive plan that will get them there.

You have to find customers, says Bastiaans that match your strengths. You have to see what’s there for you, research your new customers and be aware of the unspoken demands.

When people ask for curtains, he says, you’ve got to deliver a curtain and not just a piece of printed fabric. Find the niche for the equipment you have.