Kyocera has developed a new inkjet printhead with aqueous ink recirculation technology.

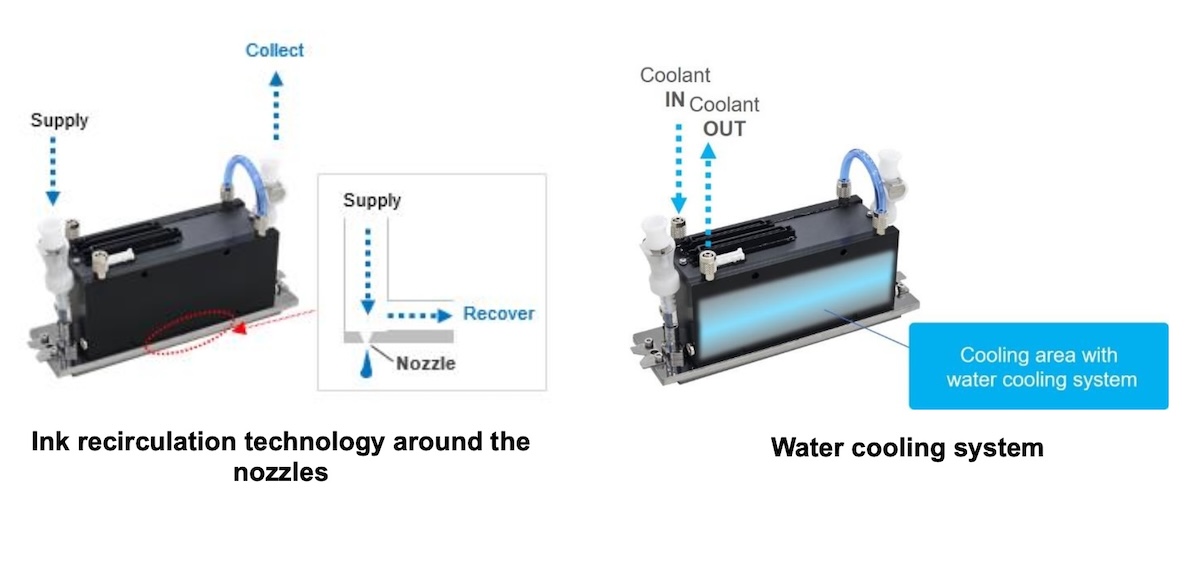

Available from April 2024, the new KJ4B-EX1200-RC recirculates ink around the nozzle, which prevents it drying there, while promoting temperature uniformity and inhibiting ink sedimentation. This is intended to allow stable printing with various kinds of inks, including fast-drying formulations, while reducing routine maintenance. This new printhead also incorporates a water cooling system4 as a standard feature, enhancing stability in continuous, high-speed printing.

By optimising the ink-flow-channel design and printhead structure, the maximum drop volume ofink ejected from nozzles has been increased to 4pL, about 43% greater than the previous model at a driving frequency of 80kHz, with improved jetting stability. Better productivity makes it possible to cover a wider range of media.

Kyocera has developed a large monolithic piezoelectric actuator, using proprietary material design technology for dense polycrystalline ceramic actuators, and manufacturing technology for thin piezoelectric ceramic substrates. The company has now optimised and adopted the technology for this printhead (width: 116 mm x depth: 34 mm x thickness: 0.04 mm). By using a large monolithic piezoelectric actuator, Kyocera said it has achieved uniform image quality within the printhead and higher print quality.